1. Upgrade Filter Media

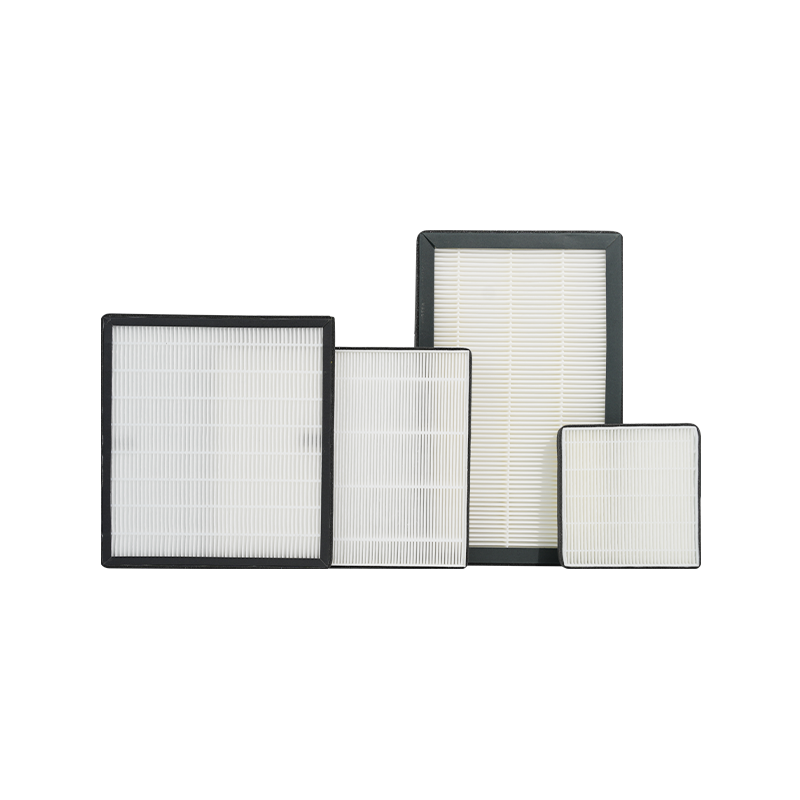

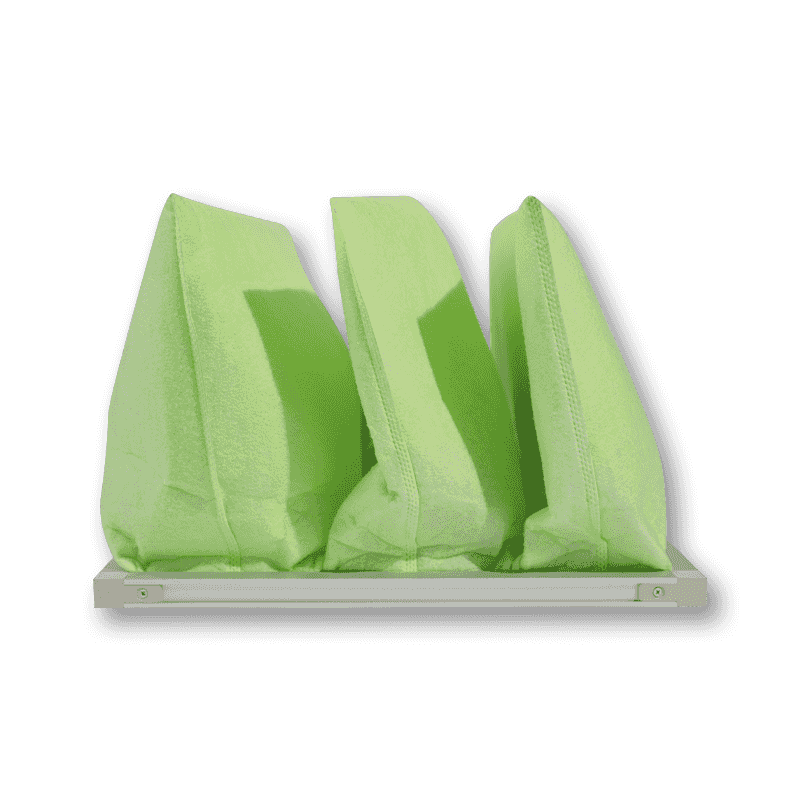

Use High-Efficiency Filters:

Many traditional dust collection systems use filter media that can only capture larger particles, which is less effective for fine particles. To improve filtration efficiency, consider switching to high-efficiency particulate air (HEPA) filters. HEPA filters can capture 99.97% of particles 0.3 microns and larger, which is especially helpful for environments with fine dust.

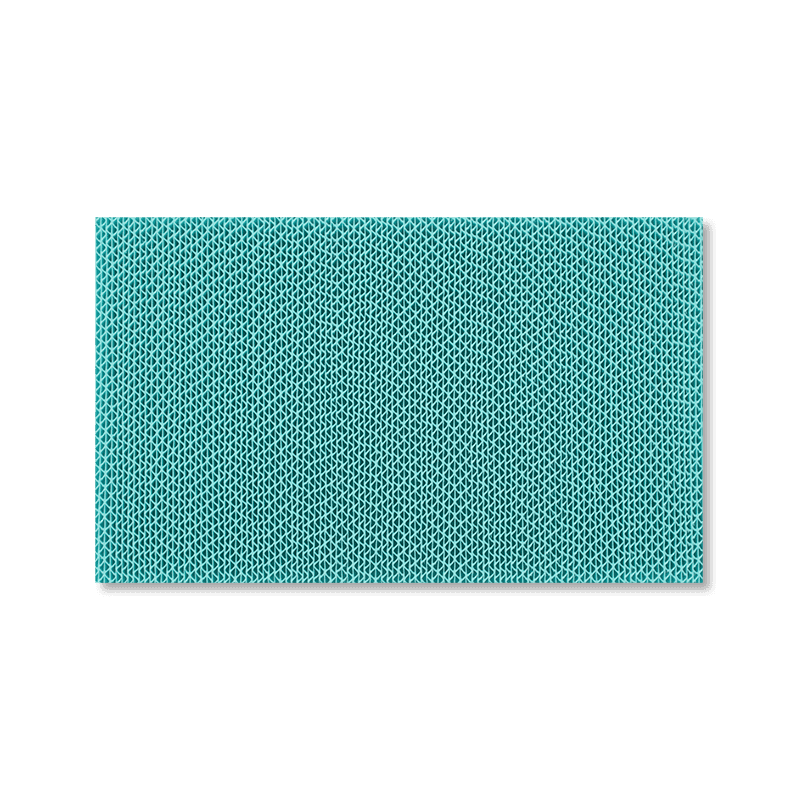

There are newer ultra-fine fiber filters that have finer fiber structures than regular fiberglass filters. These filters can capture smaller particles, boosting filtration efficiency.

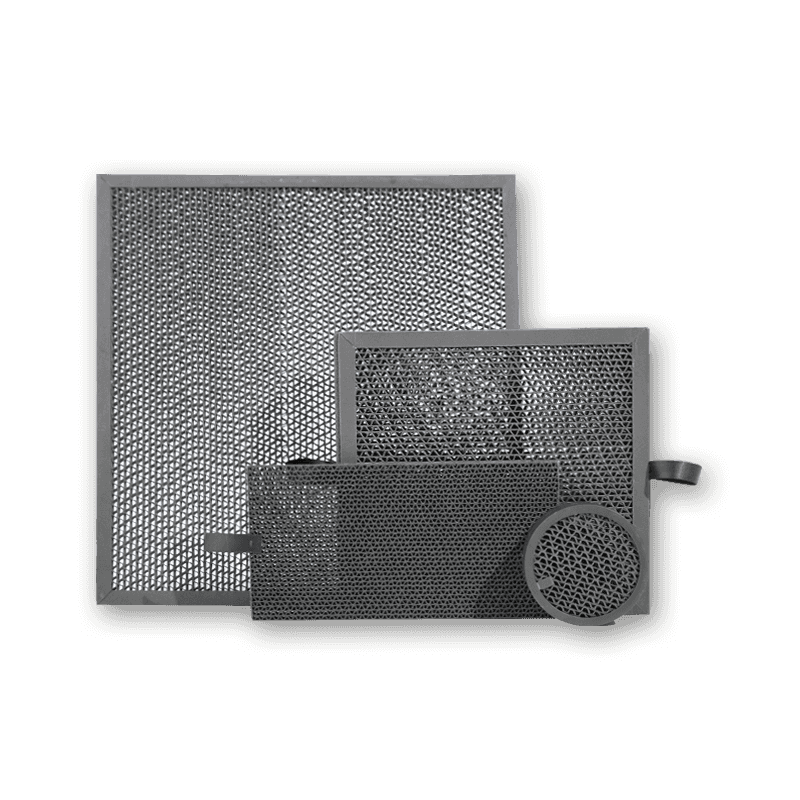

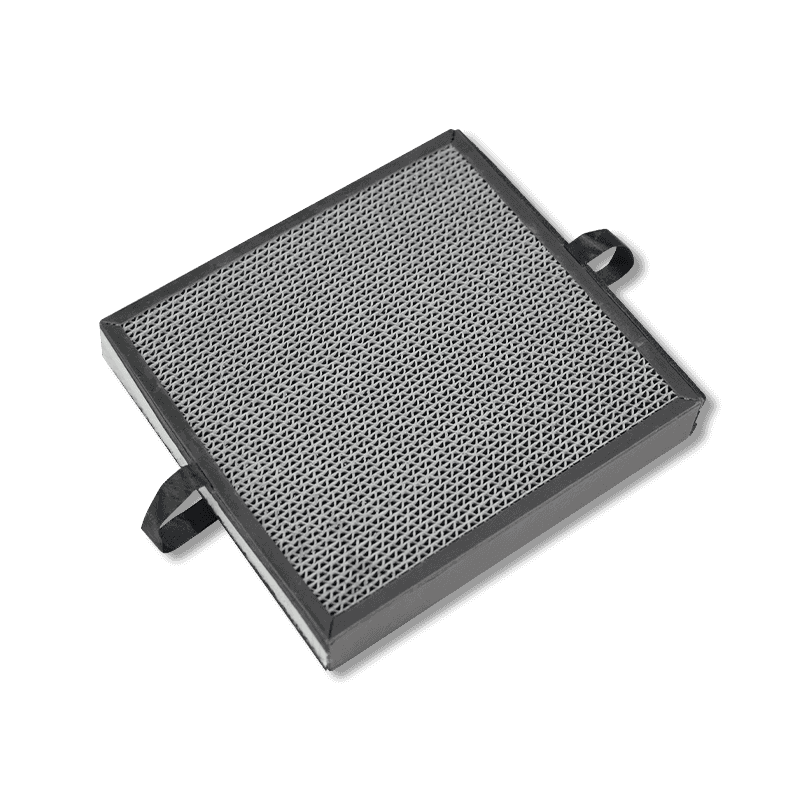

Electrostatic Filters:

Electrostatic filters use electrostatic attraction to capture dust particles. This mechanism is especially effective for filtering fine and lightweight dusts, such as smoke or oil mist. By applying an electrical charge to the filter media, dust particles are attracted and trapped on the filter surface, significantly improving filtration precision.

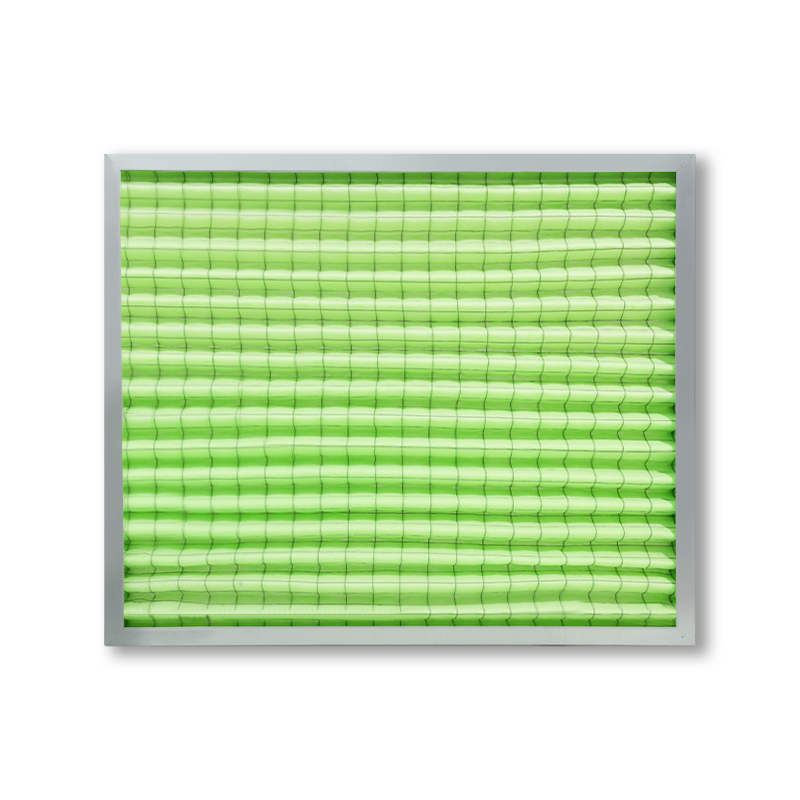

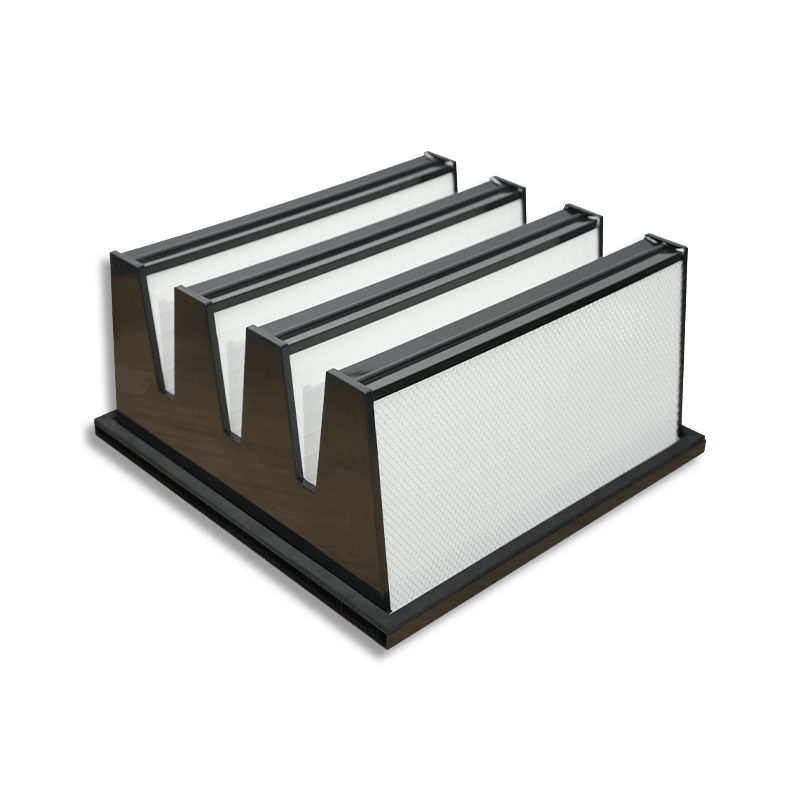

Filter Pleating Design:

The pleated design of filters increases the effective surface area, improving dust retention capacity and filtration efficiency. The pleating allows for more dust storage space without reducing airflow, which extends the life of the filter.

2. Optimize Filter Cleaning and Maintenance

Regular Cleaning:

If the filters accumulate too much dust, it can lead to reduced airflow, pressure drop, and lower filtration efficiency. Therefore, regular cleaning is key to improving efficiency. In most industrial environments, checking and cleaning filters periodically prevents dust buildup and ensures smooth system operation.

Reverse-Pulse Cleaning:

Many dust collection systems use reverse-pulse cleaning technology. By injecting compressed air to the surface of the filters, dust is periodically removed to prevent clogging. However, the pulse pressure should be adjusted based on the filter material and performance; too high a pressure can damage the filter, while too low may not clean effectively.

Monitor Filter Condition:

Using pressure differential sensors to monitor filter condition can help detect clogging or damage early. A significant increase in pressure differential usually indicates the need for cleaning or replacement, allowing for timely maintenance and preventing reduced system performance.

3. Proper Airflow Design

Airflow Optimization:

In a dust collection system, airflow design is crucial. Excessive airflow can cause dust to become airborne, while insufficient airflow may result in ineffective dust capture. Properly designing the airflow path ensures even and stable airflow across the system.

Adjusting fan speeds, duct sizes, and the location of dust pick-up points can optimize airflow. This helps avoid airflow dead zones, ensuring that every dust collection point captures dust efficiently.

Avoid Leaks:

Leaks are a common problem that reduces system efficiency, especially at ducts, joints, and connections. Leaks allow dust to escape, diminishing the filtration effect. Regularly check for and seal any leaks to maintain the system’s integrity.

Proper Duct Sizing:

The size of the ducts is critical for dust collection system performance. If ducts are too small, high air velocities will occur, leading to inefficient dust collection or even causing dust to be blown back into the environment. Conversely, ducts that are too large will result in low air velocities, reducing dust capture efficiency. Choosing the correct duct size ensures airflow remains within an optimal range.

4. Upgrade Dust Collector Type

Use Cyclones and Pre-Filters:

In many industrial settings, cyclones and pre-filters are used to remove larger particles before they reach the main filter. Cyclones use centrifugal force to separate larger dust particles from the airflow, while pre-filters capture larger dust before it enters the main filtration system. This reduces the burden on the main filter and extends its lifespan by only requiring it to handle fine particles.

Multi-Stage Filtration System:

Some high-efficiency dust collection systems use multi-stage filtration. For example, coarse dust is first removed by a rough filter, and finer particles are captured by a HEPA filter. A multi-stage system captures a broader range of particle sizes at different stages, significantly improving overall filtration efficiency.

5. Increase Dust Collector Size

If the current dust collector is not sufficient to handle the volume of dust generated in the process, consider upgrading to a larger unit. A larger dust collector can handle more airflow, capture more dust, and reduce the strain on the filters. When choosing a larger unit, make sure it matches the rest of the system (such as ducts and fans) to ensure optimal efficiency.

6. Control Humidity and Temperature

Maintain Optimal Humidity:

Excessive humidity can cause dust particles to stick together, forming larger clumps that may block filters. To maintain efficient dust collection, it's essential to control the humidity in the environment. High humidity can also cause certain types of dust, such as wood or paper dust, to stick to the filter media, affecting airflow and filtration.

Air dryers or dehumidifiers can be used to regulate humidity, ensuring the best conditions for filtration.

Temperature Control:

High temperatures can degrade filter media over time, reducing efficiency. Ensure that the temperature of the dust-laden air entering the collector is within an acceptable range for your specific filters. High temperatures can also damage certain filter materials, so proper temperature management is crucial for maintaining efficient filtration.

7. Consider the Type of Dust Collected

Particle Size Considerations:

Different types of dust particles require different filtration techniques. For example, metal dust, wood dust, and gypsum dust all have different characteristics and particle sizes. For fine particles, filters designed specifically for fine dust should be used. Larger particles can be removed by pre-filters, reducing the burden on the main filter.

Understanding the physical properties of the dust (such as particle size, density, and moisture content) helps in selecting the most appropriate filter media.

Dust Collection Hood Design:

The design of the dust collection hood is also key to improving efficiency. The hood should be placed as close as possible to the dust source to minimize the time particles remain airborne. Proper hood design ensures that dust is captured efficiently and directed toward the dust collector.

8. Utilize Dust Collection System Monitoring

Pressure Differential Sensors:

Installing pressure differential sensors before and after the filters allows real-time monitoring of filter condition. An increase in pressure drop usually indicates filter clogging, prompting timely cleaning or replacement. Monitoring this pressure differential ensures the system operates at optimal efficiency.

Airflow Monitoring:

Airflow stability is critical for dust collection efficiency. Fluctuations in airflow can indicate issues such as duct blockages or leaks. Installing airflow sensors enables quick identification of such problems, allowing for prompt corrections to keep the system running efficiently.

Real-Time Dust Load Monitoring:

Dust load sensors monitor the amount of dust entering the system. High dust load can indicate that the filters are nearing saturation or that the system's capacity is insufficient. By tracking dust load, you can proactively clean or replace filters before they become ineffective.

9. Consider Filter Replacement Frequency

Scheduled Filter Replacement:

Even with the best maintenance practices, filters will eventually degrade. Setting a regular replacement schedule ensures the system maintains high efficiency over time. In high-load or heavily contaminated environments, filters may need to be replaced more frequently.

Performance-Based Replacement:

Rather than relying on a fixed schedule, filters can be replaced based on performance metrics, such as pressure differential or airflow. This approach is more flexible and ensures that filters are replaced only when necessary, preventing premature replacements or continued use after they’ve become ineffective.

English

English Español

Español 日本語

日本語