1. Proper System Design and Sizing

1.1 Properly Selecting Dust Collection System Sizing

The Dust collection air filter must be sized based on the actual dust load and production environment. An oversized system wastes fan and ducting energy because it operates at higher capacity than required. An undersized system may not effectively collect dust, leading to increased environmental pollution and requiring higher power to compensate for the performance shortfall. The correct system size is typically determined by calculating air flow (CFM) and dust concentration. This typically involves evaluating factors such as the dust type, particle size, and dust collection locations within the production area. Using standard design calculations, such as those based on the factory's total air flow, equipment exhaust volume, and air velocity requirements, can help select the most appropriate system size. System design also requires consideration of uniform airflow distribution to avoid areas of over- or under-extraction. The dust collection system should not only meet production needs but also provide flexibility to accommodate future production changes.

1.2 Optimizing Airflow Efficiency

Airflow efficiency directly impacts the overall energy efficiency of the dust collection system. Improper duct design, especially excessive length or excessive bends, increases system air resistance, placing increased strain on the fan and increasing energy consumption. Optimizing duct layout requires not only shortening duct length and avoiding sharp bends, but also selecting the right duct diameter to minimize excessive resistance losses. Duct system design also requires considering airflow velocity and aerodynamic characteristics. Measures such as minimizing airflow variations, avoiding dead corners, and adding appropriate air intakes ensure uniform airflow. Duct material, surface finish, and internal friction also affect airflow efficiency. Using smoother inner wall materials can reduce friction, further reducing energy consumption. Proper duct design and layout not only improves dust collection system efficiency but also significantly reduces operating costs.

2. Regular Maintenance

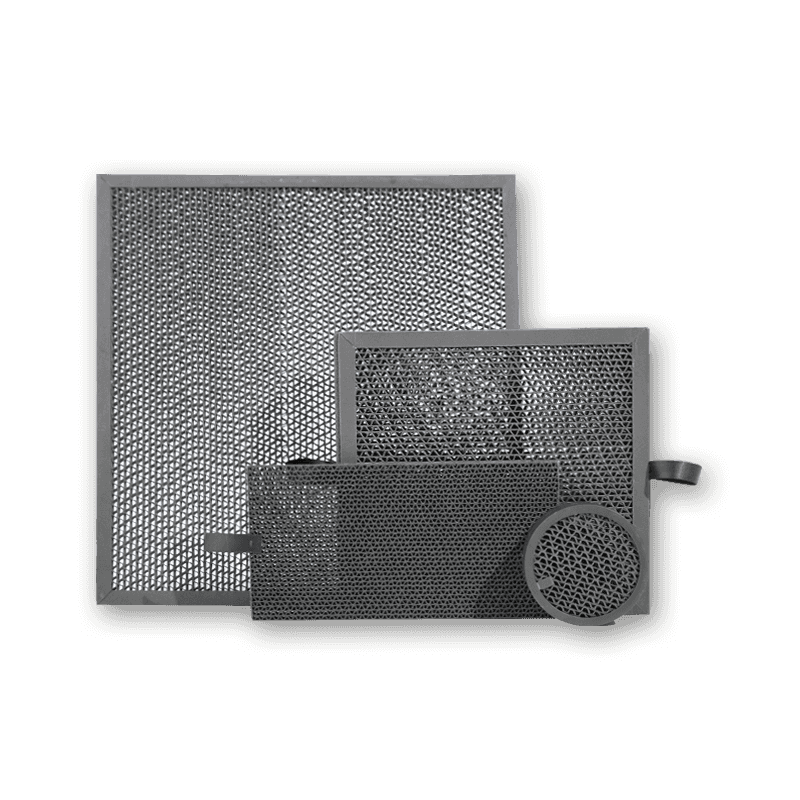

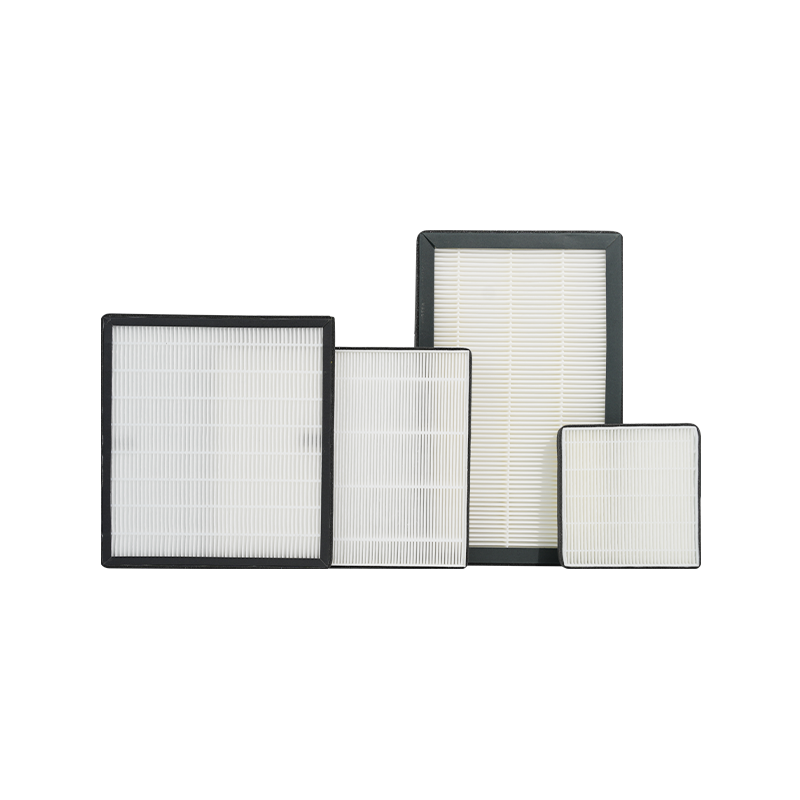

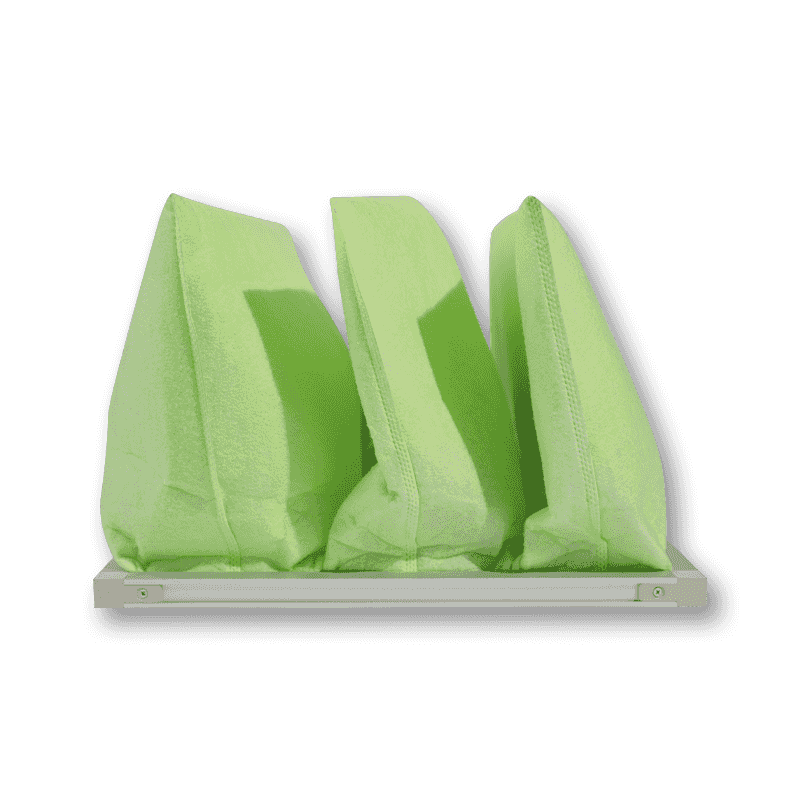

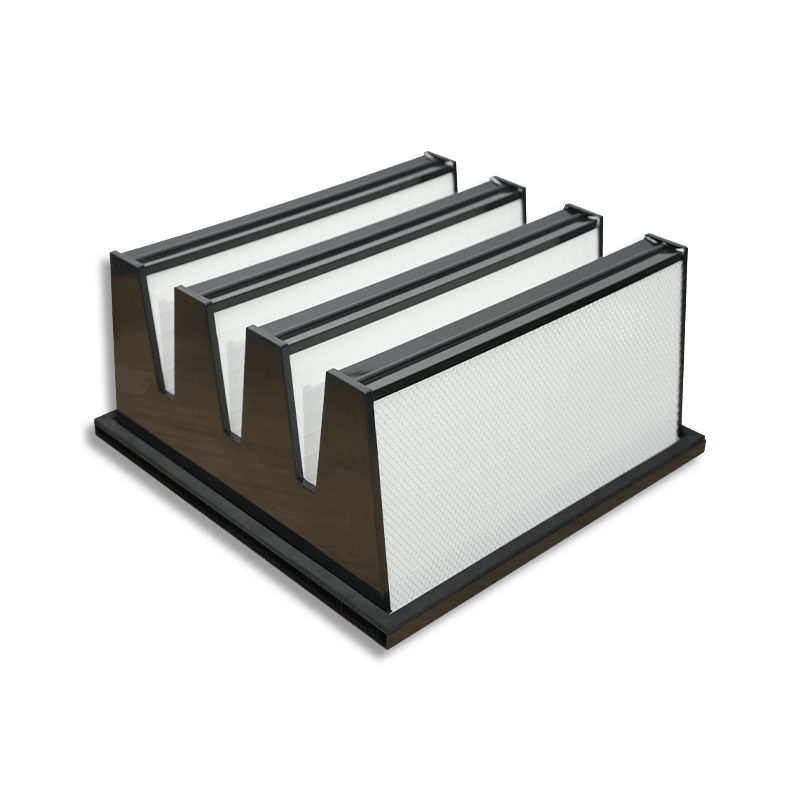

2.1 Cleaning and Replacing Filters

In dust collection systems, filters capture dust and prevent contaminants from entering the air. Over time, filters become clogged with dust, restricting air flow, causing pressure drops, and increasing system load. Therefore, regular cleaning and replacement of filters are crucial to maintaining efficient system operation. If the filter is clogged, the fan will expend more energy to push air through it, increasing system energy consumption. While each dust collection system utilizes different filter types, all systems should be equipped with a pressure differential monitoring device to monitor filter health in real time. For efficient dust collection systems, pulse jet or backflush cleaning methods can help maintain filter cleanliness. Designs should incorporate easily replaceable filters to facilitate regular maintenance. Manufacturer recommendations must be followed to promptly replace aged or damaged filters to ensure effective dust collection and energy efficiency.

2.2 Checking System Leakage

Locks are crucial for the efficient operation of dust collection systems. Any airtightness defects within the system, such as leaks in pipe connections, valves, or filter bags, can cause air loss, compromising dust collection efficiency and requiring the fan to consume more energy to compensate for the lost air. This not only increases operating costs but can also pollute the operating environment. To ensure the leaks of the dust collection system, regular inspections of joints, seals, pipe connections, and filters are essential. Common leak points include duct elbows, filter bag edges, and the air inlet of the dust collection equipment. During inspection, using methods such as airflow meters or smoke tests can visually identify leaks. Any leaks detected should be promptly repaired or replaced to reduce air loss and energy waste. Leakage inspections not only improve system efficiency but also extend equipment life.

2.3 Monitoring Filter Pressure Drop

Filter pressure drop is a key indicator of dust collection system performance. As filter dust accumulation increases, airflow resistance increases, leading to an increase in pressure drop. This increases the system's energy consumption to maintain the same air volume. Installing a pressure differential monitor allows real-time monitoring of filter status. If the pressure drop exceeds a set threshold, prompt cleaning or replacement can be implemented, avoiding decreased energy efficiency and additional energy waste. Furthermore, regularly recording and analyzing changes in filter pressure drop can help develop a reasonable maintenance plan and prevent system performance degradation caused by overlooking pressure changes. Advanced dust collection systems can also be equipped with intelligent monitoring systems that automatically analyze data to indicate filter status, enabling proactive maintenance when necessary.

3. Introducing Variable Frequency Drives (VFDs)

3.1 Installing Variable Frequency Drives (VFDs)

Variable frequency drives (VFDs) are a technology that adjusts motor speed based on load demand. By regulating fan speed, VFDs can reduce fan speed when dust loads are low, thereby reducing power consumption. In dust collection systems, dust generation is typically periodic and not constantly high. Traditional dust collection system fans typically operate at full load and cannot be adjusted to meet actual demand. With a VFD installed, the system automatically adjusts fan speed based on production conditions, ensuring efficient dust collection during high loads while avoiding unnecessary energy waste. For example, when the production line is idle or dust levels are low, the system can reduce fan speed to reduce power consumption. When production demand increases or dust concentrations rise, the fan automatically returns to an appropriate speed. The use of VFD technology in dust collection systems not only saves energy, but also extends equipment life and reduces environmental impact.

3.2 Fan Speed Optimization

Fans are one of the largest energy consumers in dust collection systems, especially under highly variable load conditions, where they often operate at full speed. Using variable frequency drives (VFDs), fan speed can be adjusted based on actual dust generation. For example, during periods of low dust generation, the system can reduce fan speed to reduce power requirements. This flexible adjustment not only ensures sufficient airflow to maintain dust collection but also avoids excessive energy consumption. As dust loads increase, fan speed automatically increases to maintain dust collection efficiency. During fan design and optimization, it is important to account for fluctuations in airflow demand and select an appropriate VFD control strategy to balance energy consumption and performance requirements. Furthermore, regular monitoring of the system's operating status to ensure proper VFD operation can further improve system energy efficiency and reliability.

4. Automatic Control and Sensors

4.1 Demand Response Control

Demand response control systems are a key optimization measure for dust collection systems. By installing sensors at key locations, parameters such as dust concentration, air velocity, and pressure differential can be monitored in real time, allowing system operation to be automatically adjusted based on this real-time data. For example, a dust collection system can automatically turn fans and filters on and off based on the start and stop of the production line, avoiding energy consumption when the system is not in operation. During production, if dust concentrations are low, the system can reduce fan speed or shut down some equipment to reduce unnecessary energy consumption. Sensor data can be integrated with the automated control system to enable intelligent system adjustments. This demand-based control approach not only optimizes energy use but also improves system responsiveness and efficiency, reducing equipment wear and tear.

4.2 Real-time Data Monitoring

Real-time data monitoring provides constant visibility into the operating status of the dust collection system, helping to promptly identify potential problems and implement appropriate optimization measures. Various components of the dust collection system, such as fans, filters, and ducts, can be equipped with monitoring sensors that provide real-time data feedback. This data, including pressure differential, airflow, energy consumption, temperature and humidity, can help operators analyze system performance and optimize it. For example, pressure differential monitoring can promptly identify filter blockages or duct leaks, enabling appropriate cleaning or repair measures. Real-time data can also be centrally analyzed via a cloud platform or local control center, facilitating timely decision-making by management. Through data-driven decision-making processes, not only can energy waste be reduced, but the life of equipment can also be extended, improving the overall efficiency of the system.

5. Optimize Dust Hood and Duct Design

5.1 Proper Dust Hood Design

Dust hood design is crucial to dust collection efficiency. If the hood design does not meet process requirements or fails to effectively capture dust, the system will not function effectively, resulting in low dust collection efficiency. When designing the hood, factors such as the distance from the dust source, the type of dust, and airflow velocity should be considered. The shape and size of the hood should be customized to the operating characteristics of the production equipment to avoid excessive airflow dead zones and blind spots. For some high-intensity dust sources, the hood may require multiple intake ports or a layered structure to improve dust capture efficiency. Proper hood design can help reduce the burden on the fan and other system components, ensure even airflow distribution, and avoid localized over- or under-intake. Furthermore, operational safety must be considered during design to prevent the hood from impacting workers during operation.

5.2 Optimize Duct Layout

The duct is a critical component in the dust collection system, carrying air flow. Its layout directly affects airflow efficiency and energy consumption. The goal of optimizing duct layout is to reduce resistance to air flow and improve system efficiency. The total length of ducts should be minimized, avoiding unnecessary bends and long transmission distances. Each bend and joint increases airflow resistance, requiring the fan to consume more energy to overcome this resistance. The duct diameter should be sized appropriately for the airflow volume. Avoid oversized ducts that result in low airflow velocity, or undersized ducts that result in excessive airflow, which increases resistance. Choosing the right duct material is also crucial. For example, smooth metal ducting, rather than rough PVC, effectively reduces friction and further improves airflow efficiency. Regularly inspecting duct cleanliness to prevent additional resistance caused by dust accumulation is also key to optimizing the duct system.

6. Reducing Dust Re-entry Rate

6.1 Installing a Cyclone Separator

A cyclone separator is a device used to separate large dust particles. It works by using centrifugal force to separate larger dust particles from the airflow, reducing the amount of dust entering subsequent filters. Installing a cyclone separator can effectively reduce the burden on filters, extending their lifespan and reducing the frequency of cleaning and replacement. Cyclone separators are particularly suitable for handling heavy loads of dust, such as large particles and coarse dust. Most cyclones do not require external power; they utilize the natural motion of the airflow to separate dust, significantly improving the system's energy efficiency. Cyclones also increase the overall system's processing capacity, enabling the dust collection system to handle higher levels of dust generation. By properly selecting the size and type of cyclone separator, the majority of coarse dust can be effectively removed before entering the primary filtration system, reducing energy consumption for subsequent treatment.

6.2 Using Air Flow Simulation

Computational Fluid Dynamics (CFD), a technique that uses computational fluid dynamics to simulate airflow paths, can help optimize dust collection system design. CFD simulations can predict and analyze airflow behavior during the design phase, identifying potential dead zones, turbulent areas, and areas of airflow inefficiency. Using this data, designers can optimize the design of ducting, hoods, and other components to improve overall dust collection efficiency. CFD simulations can identify issues that are difficult to detect using traditional design methods, such as choppy transitions in duct layouts and inappropriate dust hood design, thereby providing more targeted optimization solutions. CFD technology can also be used to compare different design options, select the optimal path, and avoid unnecessary energy waste. Through scientific modeling and simulation, detailed optimization and adjustments can be made before the system is operational, improving the efficiency of the dust collection system.

7. Use High-Efficiency Filter Materials

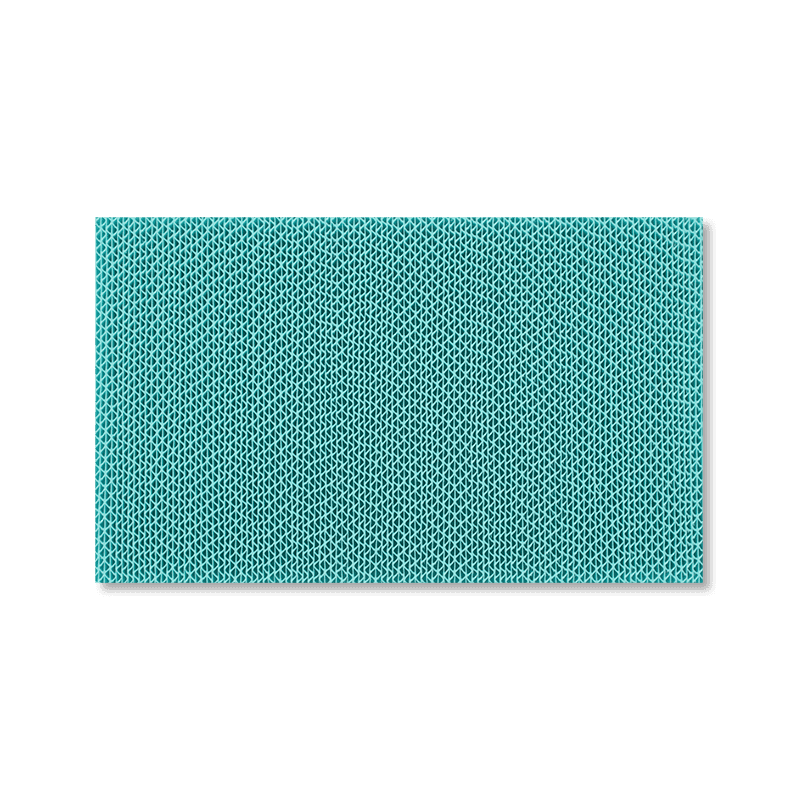

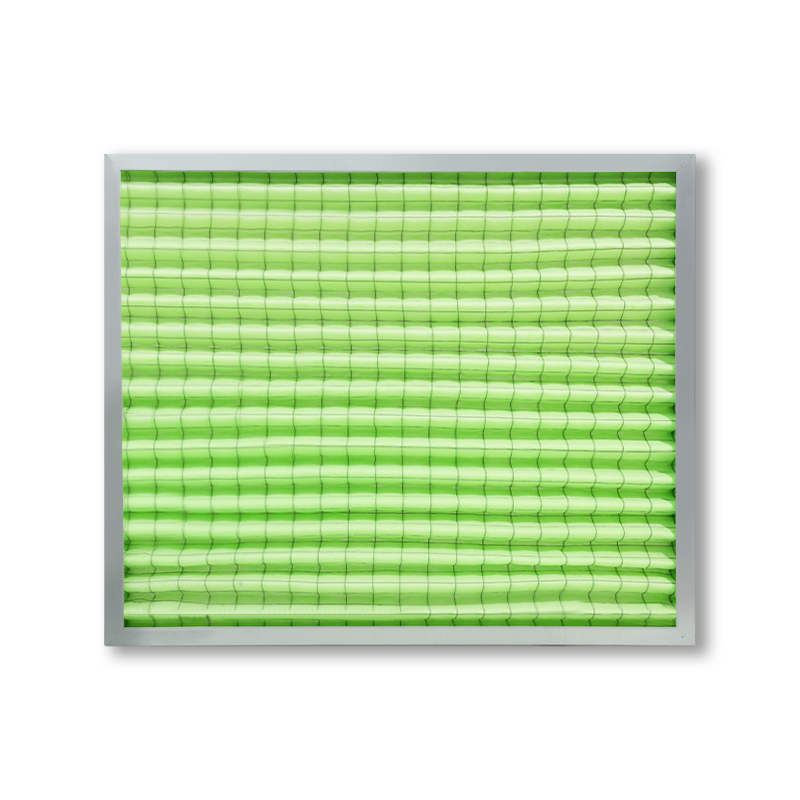

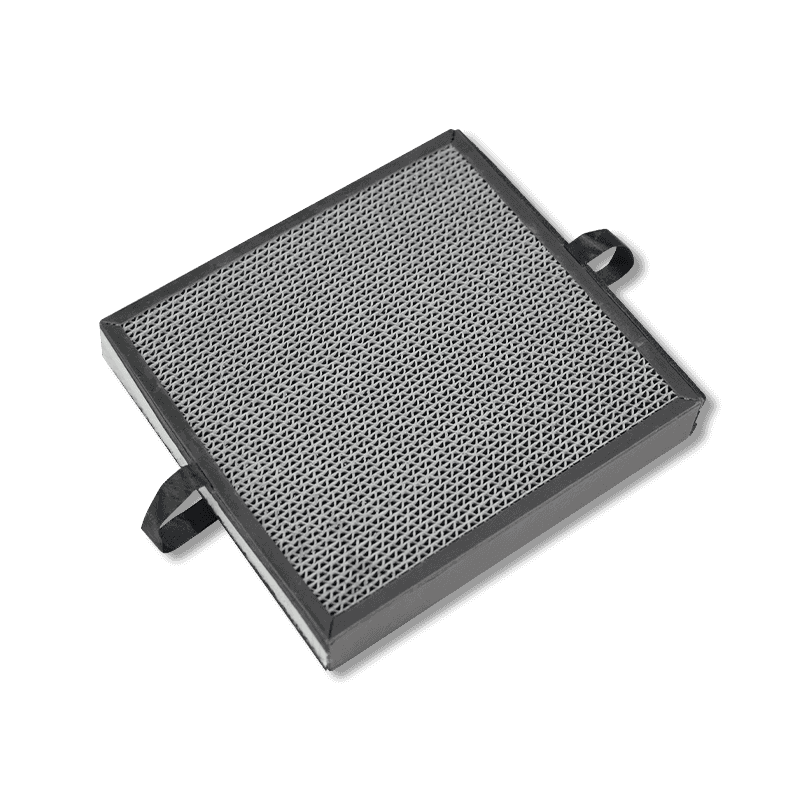

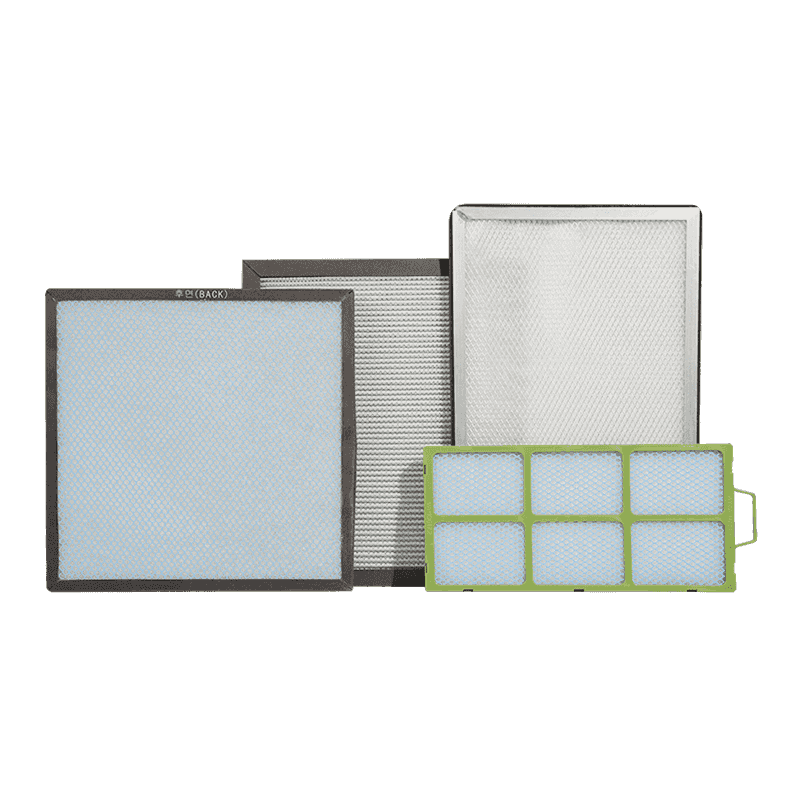

7.1 Selecting High-Efficiency Filter Materials

The choice of filter material directly impacts the efficiency of the dust collection system. Modern dust collection systems are no longer limited to traditional fiber filter materials. Many new high-efficiency filter materials, such as nanofiber filter cloth and polyester composite materials, offer lower airflow resistance and higher dust collection efficiency. These high-efficiency filter materials can capture even finer dust particles, especially those that are more effective in capturing fine dust such as PM2.5. These materials also offer improved air permeability, enabling efficient filtration without significantly increasing energy consumption. Selecting high-efficiency filter materials not only improves dust collection efficiency but also reduces filter pressure drop, thereby reducing system energy consumption. In actual applications, the most appropriate filter material should be selected based on the dust properties (such as particle size and humidity) and the requirements of the operating environment. For example, environments with high humidity or high levels of oily dust require special oil- and water-resistant materials.

7.2 Jet Cleaning Technology

Pulse jet cleaning is a common method for cleaning filters in dust collection systems. It uses rapid bursts of compressed air to flush away dust adhering to the filter surface. This cleaning method not only effectively restores filter air permeability but also reduces maintenance costs. When designing a dust collection system, the layout of the pulse jet system should be optimized to match the filter's operating conditions. The jet interval and intensity should be adjusted based on dust concentration and filter clogging to avoid excessive jetting that wastes energy or damages the filter. Regular pulse jet cleaning can effectively reduce filter pressure drop, maintain a stable air flow, and reduce the burden on the fan. In conjunction with an automated control system, the pulse jet cleaning process can automatically adjust the cleaning frequency and intensity based on real-time monitoring data, achieving efficient and energy-saving cleaning.

8. Upgrade Equipment to Improve Energy Efficiency

8.1 Use High-Efficiency Motors

In dust collection systems, electric motors are one of the major sources of energy consumption. With the continuous advancement of technology, many modern motors have achieved higher energy efficiency ratios. By adopting these high-efficiency motors, the energy consumption of dust collection systems can be significantly reduced. Compared with traditional motors, high-efficiency motors consume less electricity under the same load conditions, reducing unnecessary energy waste. High-efficiency motors are often designed with advanced materials and more sophisticated manufacturing processes, which enable them to maintain lower operating temperatures and minimize energy losses even during long-term operation. High-efficiency motors generally have a longer service life, reducing maintenance frequency and repair costs. Considering replacing older dust collection systems with high-efficiency motors is an effective energy-saving strategy, especially for systems that require long-term operation or operate under heavy loads.

8.2 Selecting Energy-Efficient Fans

Fans are one of the major energy consumers in dust collection systems, making their selection crucial for energy conservation. Energy-efficient fans utilize a more efficient design, providing the same airflow with less energy consumption. Compared to traditional fans, energy-saving fans are typically designed with greater emphasis on optimizing airflow paths and reducing airflow resistance. They employ efficient impeller and fan housing designs, thereby minimizing energy losses during airflow. Using high-efficiency fans not only reduces power consumption but also reduces fan failures, improving system reliability. The advantages of energy-saving fans are particularly pronounced in systems operating over a long period of time. Selecting the appropriate fan specifications and models, and regularly adjusting fan speed according to actual operating conditions, are key measures for achieving energy savings.

9. Optimizing Operation Schedules

9.1 Leveraging Peak Hours

The workload of dust collection systems often fluctuates with production process fluctuations. Therefore, rationally scheduling the dust collection system's operating hours can avoid unnecessary energy consumption. For example, high-load periods on a production line typically require higher dust collection capacity, while low-load periods can reduce fan operating power or even shut down certain equipment. By optimizing the production cycle, the dust collection system's high-energy consumption can be concentrated during times when efficient dust collection is required, while system operation can be reduced during periods of lower demand, avoiding resource waste.

9.2 Implementation of Automated Control

Automated control enables the dust collection system to adjust its operating status based on actual needs, thereby optimizing energy utilization. For example, sensors can monitor air quality, dust concentration, and production line operating conditions in real time, and a PLC control system can intelligently adjust fan speed or start and stop. Automated control systems eliminate errors caused by manual adjustments and ensure that the dust collection system always operates at optimal conditions. Automated control also effectively records system operating data, helping operators analyze energy consumption trends and make adjustments.

English

English Español

Español 日本語

日本語