1. Clogged or Blocked Filters

Problem: Over time, filters accumulate dust and debris, which can obstruct airflow and reduce system efficiency. A clogged filter can also cause a high pressure differential, increasing the energy consumption of the equipment.

Solution:

Regular Maintenance: Clean or replace filters regularly depending on the operating environment. Typically, this should be done every 6 months or according to air quality requirements. Use cleaning devices such as air pulse systems, vibration mechanisms, or reverse airflow for self-cleaning.

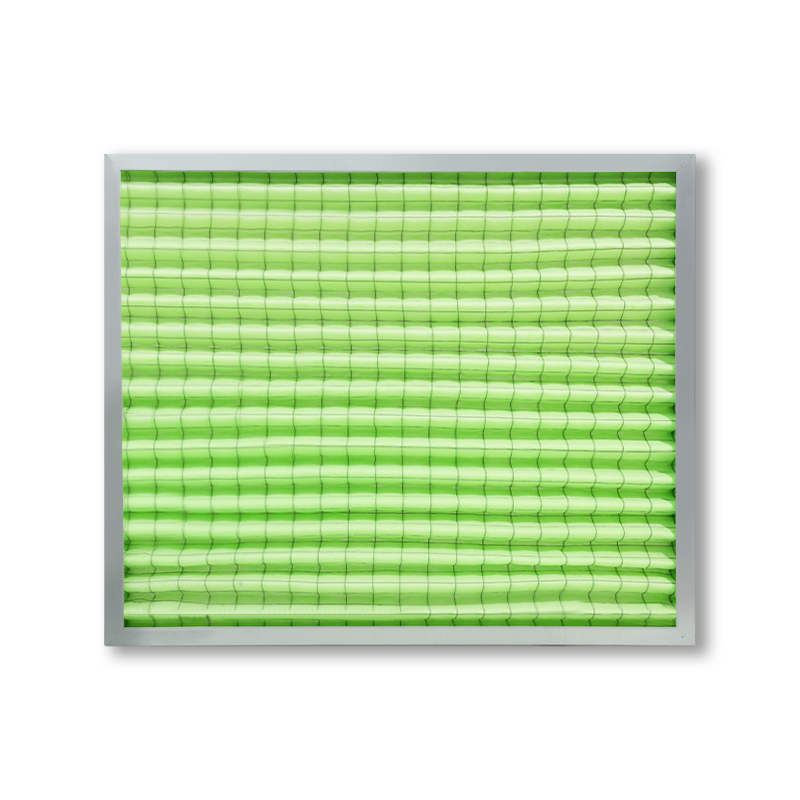

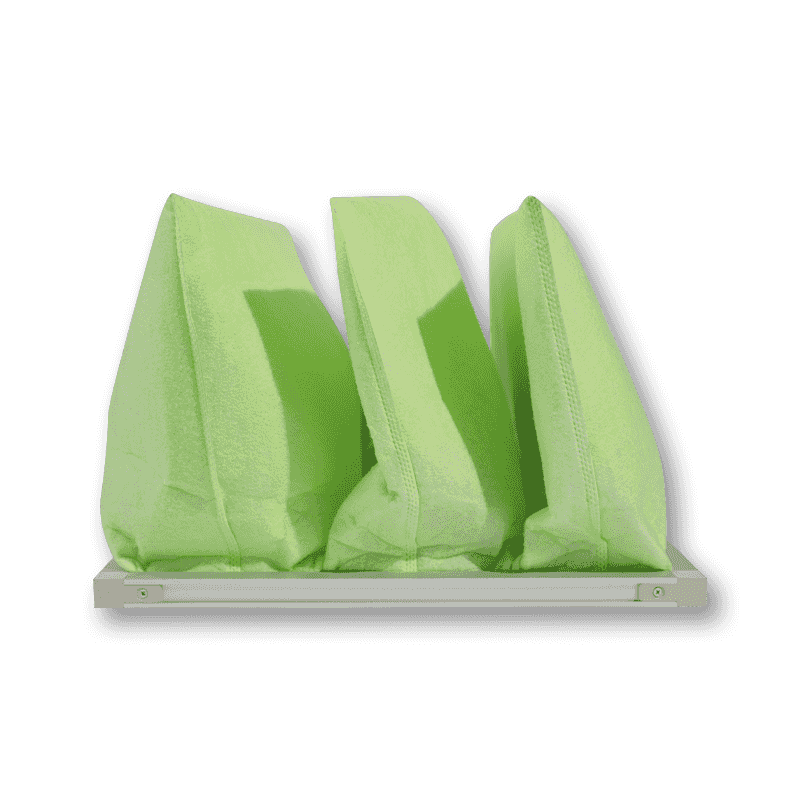

Pre-Filters: Install pre-filters to capture larger particles before they reach the main filters. This reduces the load on the primary filters and prevents clogging.

Automated Cleaning Systems: Some dust collection systems are equipped with self-cleaning features, such as mechanical shaking or pulse jet cleaning systems, which clean filters periodically to prevent clogging.

Monitor Pressure Drop: Regularly monitor the system's pressure differential, as a high pressure drop can indicate a clogged filter. When pressure readings exceed a specified range, it’s time to clean or replace the filters.

2. Inefficient Filtration

Problem: Even if the Dust collection air filter appear clean, airflow may still be compromised, or fine dust particles may escape from the system.

Solution:

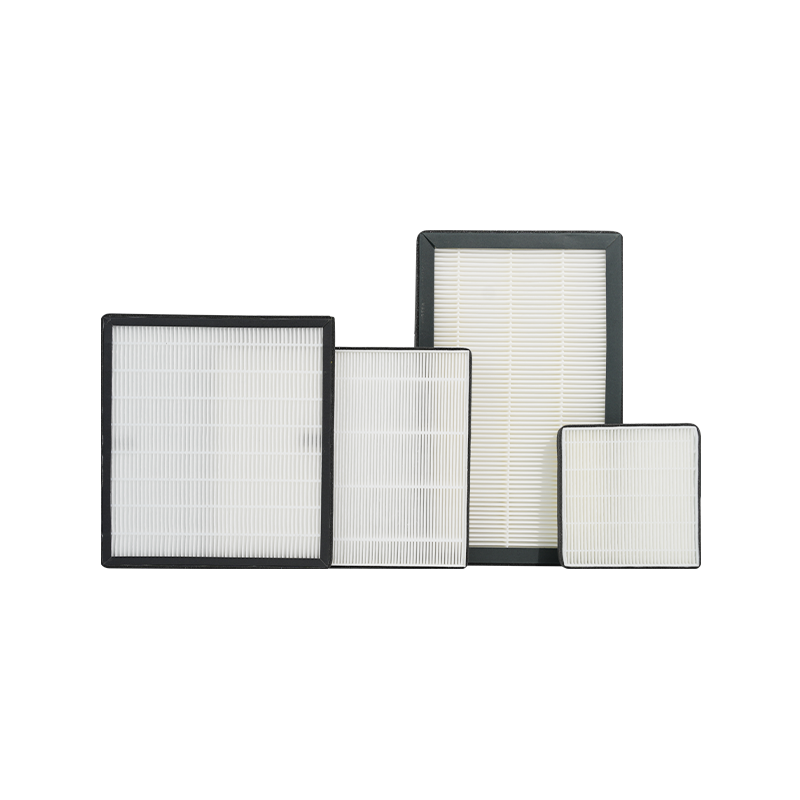

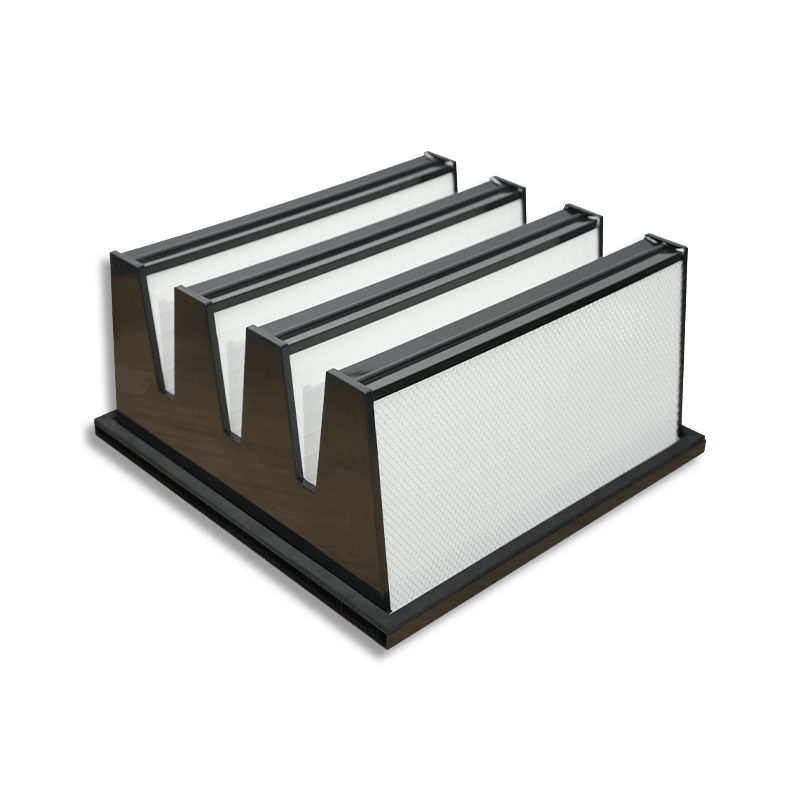

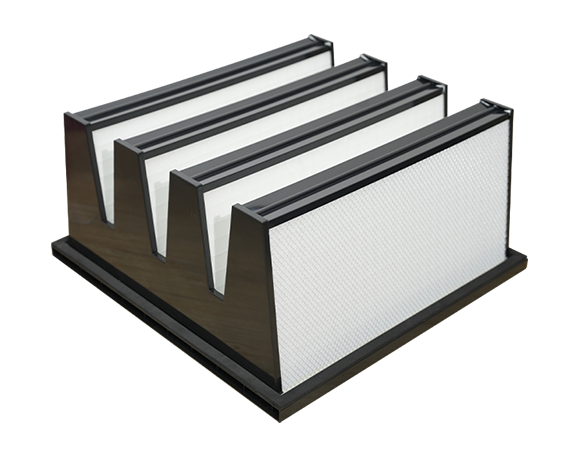

Check Filter Type: Ensure the filter media is appropriate for the type of dust being collected. For very fine particles, use high-efficiency filters such as HEPA filters or cartridge filters that can capture 99.97% or more of the smallest particles.

Proper Sizing: Ensure the filter surface area and airflow rating match the system’s design requirements. If the filter is too small, it will impede airflow; if too large, it may waste energy.

Seal the Gaps: Ensure the filter is properly sealed in the housing, as leaks can bypass the filter and allow dust to escape into the air, reducing filtration efficiency.

3. High Differential Pressure

Problem: High differential pressure in the system may be caused by clogged filters, air leaks, or fan malfunction, leading to inefficient operation and potential system damage.

Solution:

Check for Air Leaks: Inspect the ductwork, connections, and filter housing for any air leaks. Leaks can reduce dust collection efficiency and cause system instability.

Clean or Replace Filters: If filters are contaminated or clogged, cleaning or replacing them can restore normal airflow and reduce pressure differential.

Adjust Fan Speed: If the fan is running too fast, it can create excessive pressure differential. Adjust the fan speed to an optimal level to avoid unnecessary energy consumption.

4. Damaged Filters

Problem: Filters may become torn, punctured, or damaged over time, allowing dust to bypass and contaminate the air.

Solution:

Regular Inspections: Perform visual inspections of the filters to check for signs of damage, such as tears or holes. Early detection can prevent dust leakage.

Replace Damaged Filters: If a filter is damaged, it should be replaced immediately to maintain system performance.

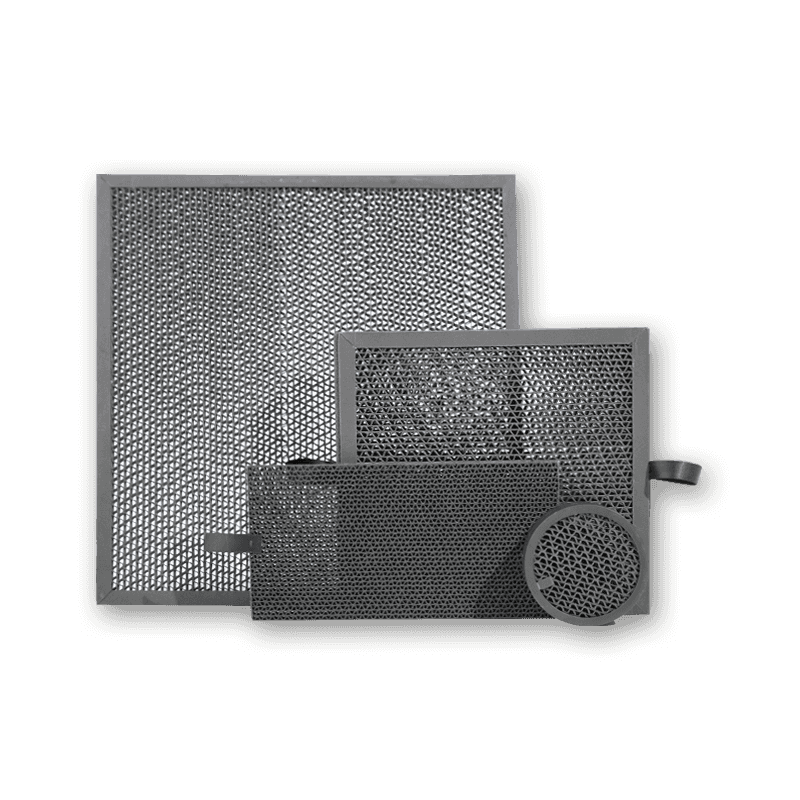

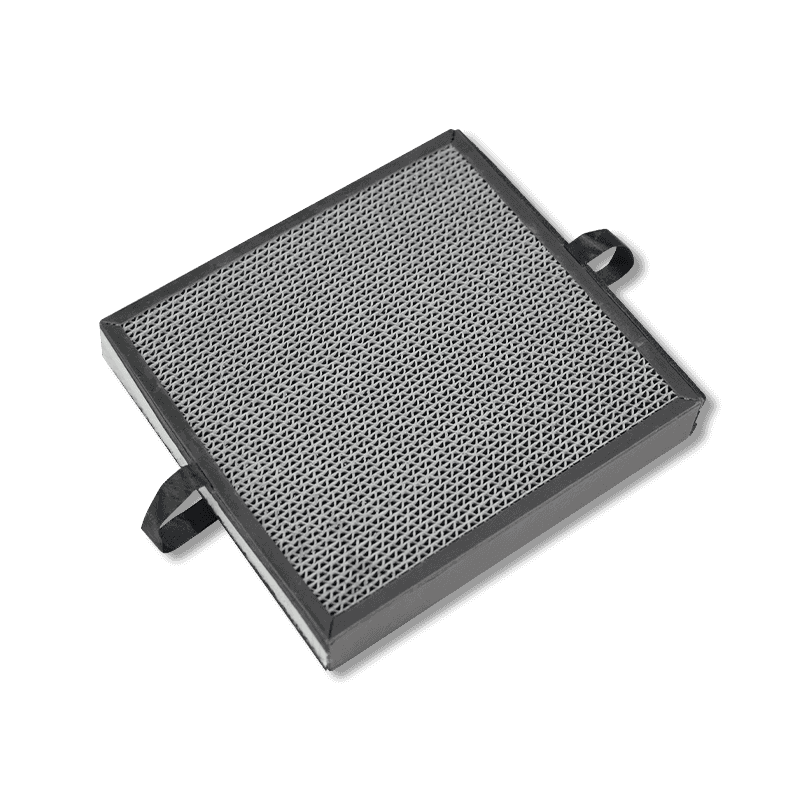

Use Durable Filters: Consider using more durable filter materials, such as synthetic or metal mesh filters, which are suitable for handling coarse particles or high-temperature environments.

5. Unbalanced or Poor Airflow

Problem: Unbalanced or insufficient airflow can lead to inadequate dust collection in some areas, or cause airflow bottlenecks that reduce overall system efficiency.

Solution:

Optimize Ductwork Design: Ensure the system's ductwork is properly designed, with appropriately sized ducts and minimal bends or obstructions. This helps reduce airflow resistance and ensures even distribution.

Check the Fan and Motor: Inspect the fan and motor for proper operation. If the fan is inefficient or malfunctioning, airflow will be insufficient. Adjust the fan speed or replace faulty components.

Airflow Monitoring: Use an airflow meter to measure actual airflow throughout the system. Ensure that airflow is evenly distributed across all filters and duct sections. If certain areas have insufficient airflow, consider adjusting the duct configuration or fan performance.

6. Excessive Dust Build-Up

Problem: In environments with high dust levels, dust may build up quickly in the system, causing reduced efficiency or even posing a fire hazard.

Solution:

Increase Cleaning Frequency: In highly dusty environments, increase the cleaning frequency of the dust collection system. Perform checks and cleaning on a daily or weekly basis to prevent excessive dust accumulation.

Use Explosion-Proof Filters: If dealing with combustible dust, use explosion-proof filters or systems designed for such environments. These filters are designed to handle high-risk dust types safely.

Install Fire Suppression Systems: For systems handling combustible dust, install fire suppression systems to prevent potential dust ignition and subsequent fire hazards.

7. Poor Filter Life

Problem: Filters are wearing out too quickly, resulting in frequent replacements and higher operating costs.

Solution:

Optimize Airflow: Ensure that the airflow and dust load in the system are within the design parameters. Excessive airflow or dust levels will shorten the life of the filters.

Upgrade Filter Material: Consider using filter materials with a longer lifespan and greater dust-holding capacity. This helps reduce the frequency of replacements.

Adjust System Operation: Depending on the operational environment, adjust the system's operating frequency and fan speed. Reducing fan speed can sometimes extend the life of the filters.

8. Filter Odor or Mold Growth

Problem: Moisture in the dust collection system can cause filters to develop unpleasant odors or even grow mold.

Solution:

Ensure Proper Ventilation: Make sure the dust collection area is dry and well-ventilated. Excess moisture can encourage mold growth and foul odors.

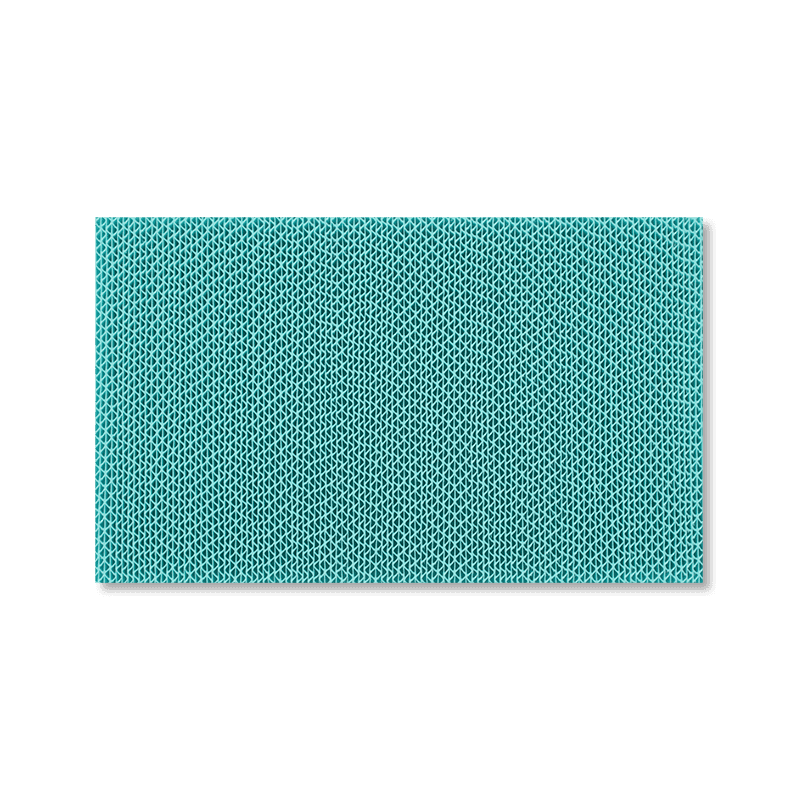

Use Moisture-Resistant Filters: Choose filters designed to withstand humid conditions, or use desiccants to control moisture in the system.

Regular Cleaning and Replacement: Regularly clean and replace filters to prevent the accumulation of organic matter, which can lead to mold growth and odors.

9. High Energy Consumption

Problem: Dust collection systems may become inefficient in terms of energy consumption if the filters are too restrictive or dirty.

Solution:

Optimize System Design: Ensure that the dust collection system is designed to meet the required airflow without being oversized or undersized. Proper ductwork and fan sizing can reduce energy consumption.

Use Low-Resistance Filters: Choose filters with lower resistance to airflow, as this will help improve efficiency and reduce energy consumption.

Install Variable Speed Drives (VSD): A variable speed drive on the fan motor can help adjust the fan speed according to the system's demands, reducing energy usage when full power is not required.

10. Excessive Noise

Problem: Dust collection systems may generate excessive noise, often due to airflow resistance, fan issues, or poor system design.

Solution:

Check for Blockages: Ensure there are no blockages or restrictions in the system that could cause the fan to work harder, thus generating more noise.

Inspect Fan Blades: Worn or damaged fan blades can cause excessive noise. Inspect and replace any damaged blades to reduce noise levels.

Install Mufflers or Silencers: Add mufflers or silencers to the intake and exhaust parts of the system to help reduce noise levels.

English

English Español

Español 日本語

日本語