1. Capture and Contain Dust Particles

Dust collection systems are essential for trapping airborne dust particles and preventing them from circulating in the air. In industrial and workshop environments, these systems help maintain clean air and reduce the health risks associated with dust. Dust collection systems come in various types, including bag filters, cartridge filters, and HEPA filters, each designed for different dust particle sizes and purposes.

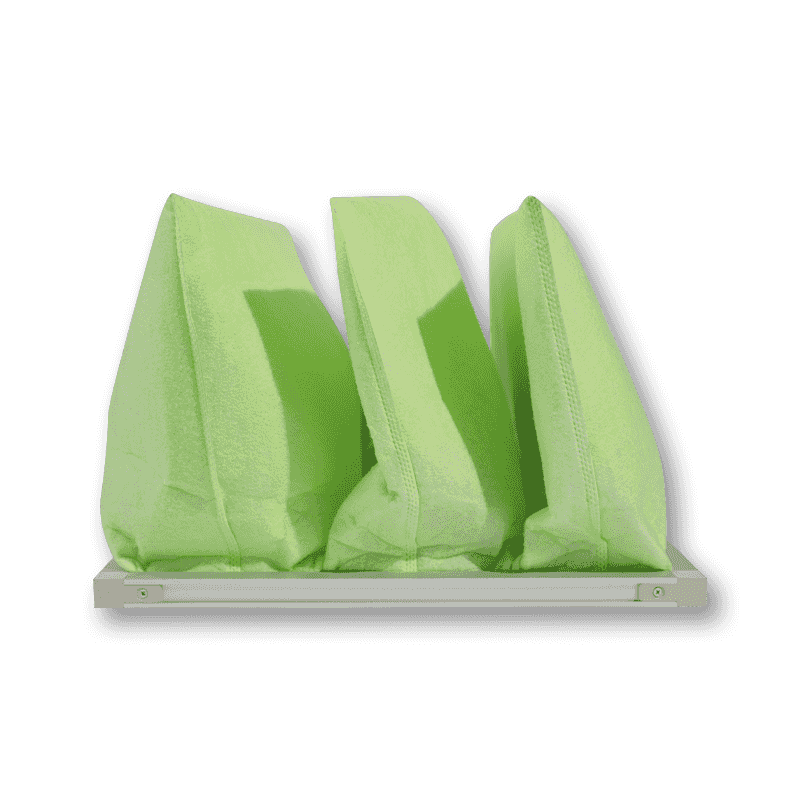

Bag Filters: Typically used for larger dust particles, these are common in general industrial settings and offer good efficiency and long service life.

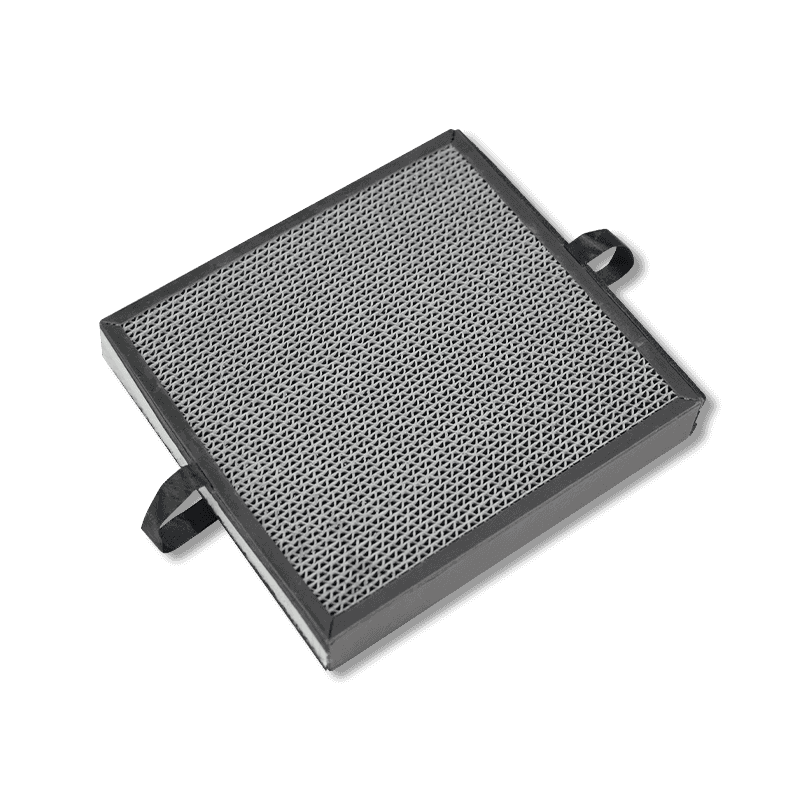

Cartridge Filters: Suitable for capturing finer dust particles, these filters are compact and can handle higher airflow.

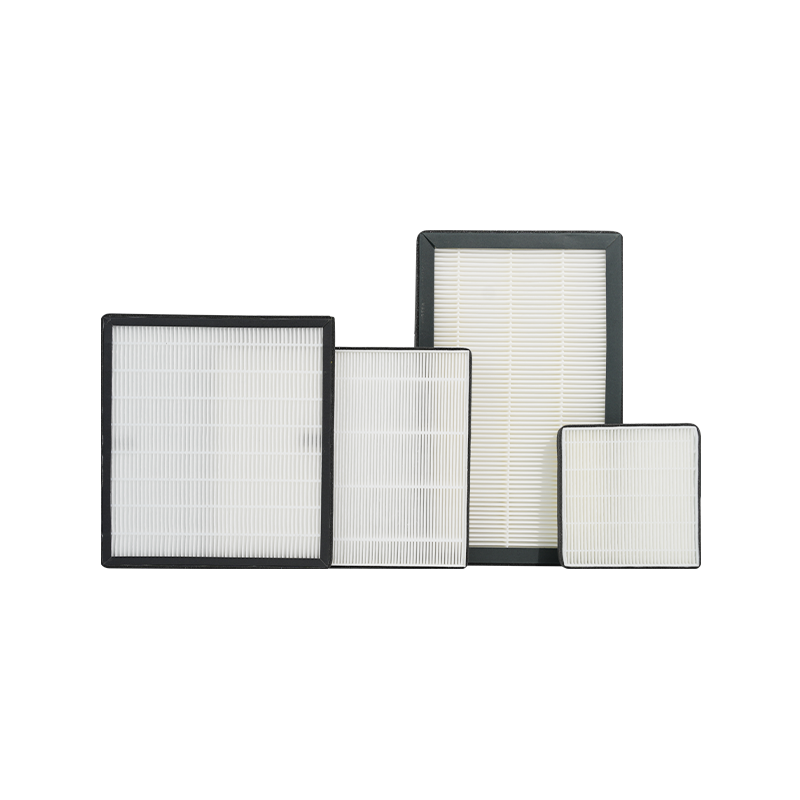

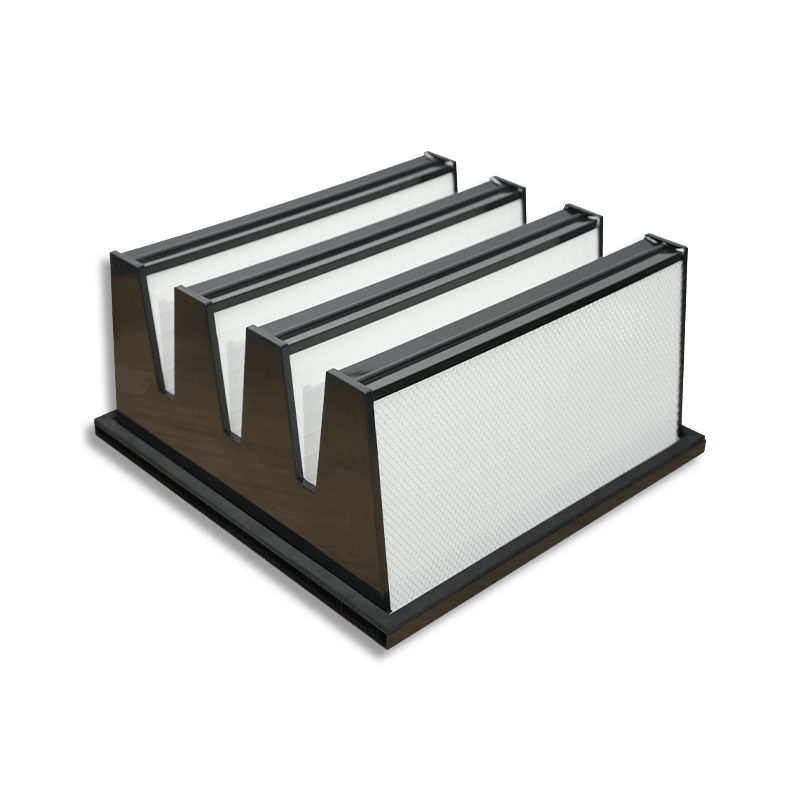

HEPA Filters: High-efficiency filters that can capture 99.97% of particles as small as 0.3 microns. They are often used in environments that require stringent cleanliness standards.

These various filters work together to trap dust effectively, ensuring improved air quality and protecting workers' health.

2. Filtration Mechanisms

The effectiveness of dust collection systems relies on the design and operation of their filters. There are several filtration mechanisms that contribute to the system’s ability to capture dust:

Inertial Impaction: Larger particles are unable to follow the airflow due to their size and velocity, causing them to collide with the filter fibers and get captured. This mechanism primarily targets larger dust particles.

Interception: Medium-sized particles follow the airflow closely but come into contact with the filter fibers due to their size, thus getting trapped.

Diffusion: Very fine particles move erratically and are more likely to collide with gas molecules, making it easier for them to be captured by the filter fibers.

These mechanisms combine to ensure that the filter can efficiently capture dust particles of various sizes and types, improving the overall efficiency and cleanliness of the system.

3. Filter Materials and Design

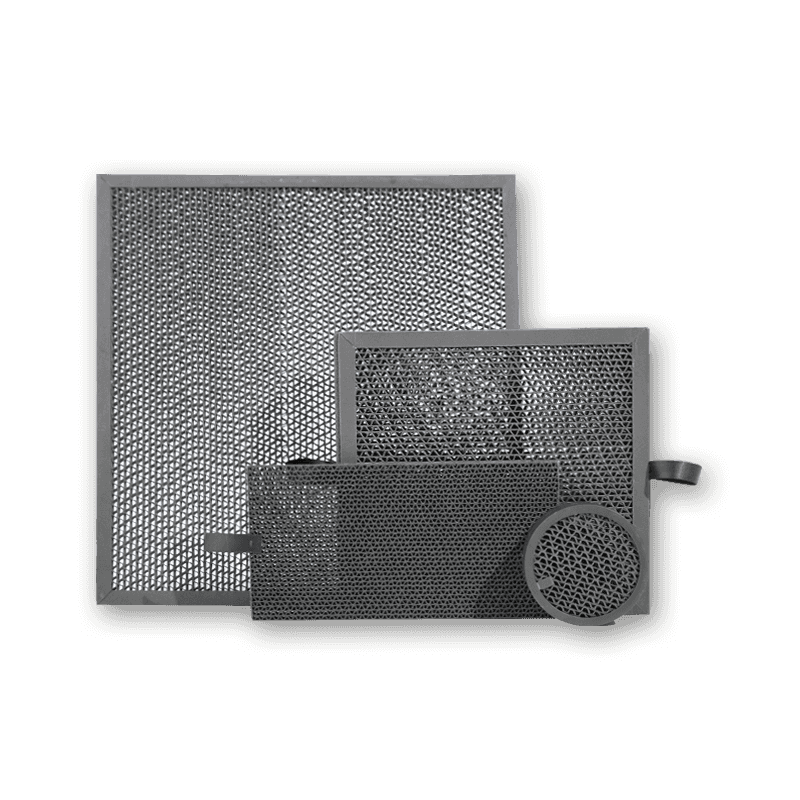

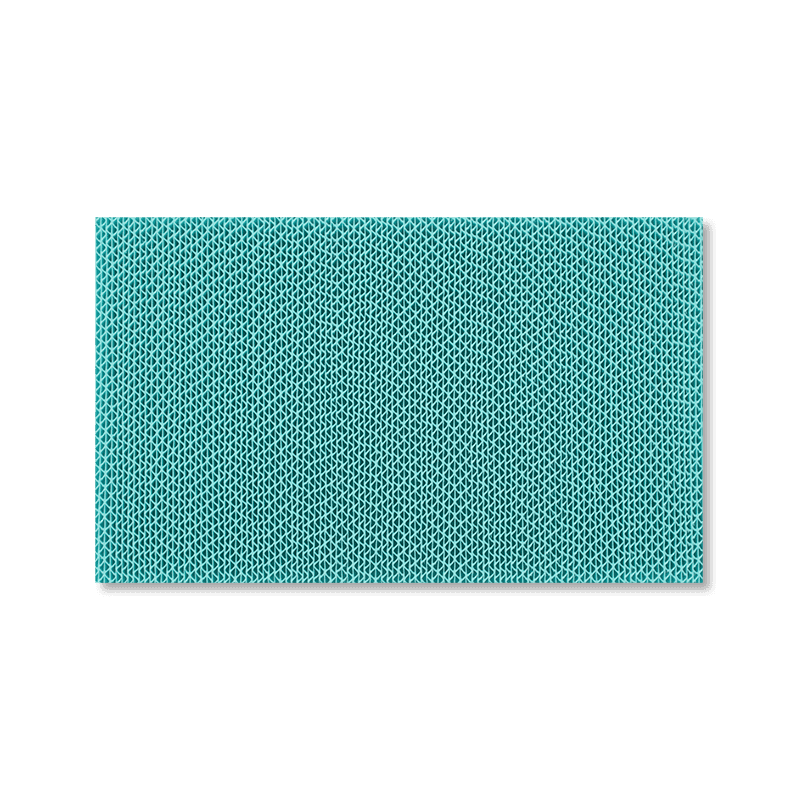

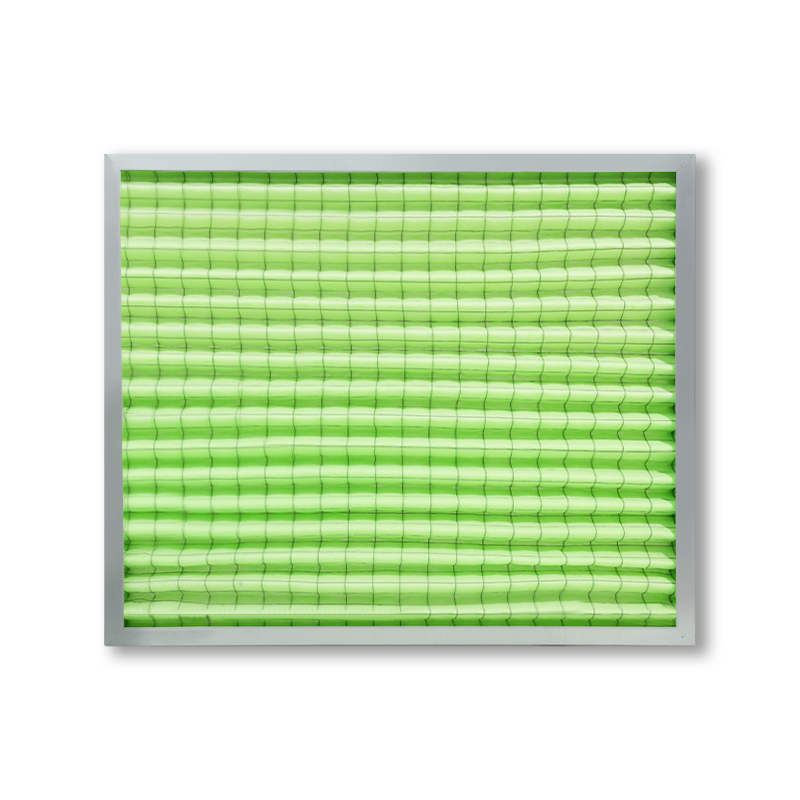

The material and design of the filters are crucial for their performance. Choosing the right filter material can improve filtration effectiveness, extend service life, and enhance overall system efficiency. Common filter materials include:

Polyester: Durable and affordable, polyester filters effectively capture larger dust particles and are widely used in industrial environments.

Nomex (High-Temperature Nylon): Known for its heat resistance, Nomex is used in high-temperature environments such as metalworking, ceramics, and more.

PTFE (Polytetrafluoroethylene): This material is resistant to chemicals and moisture, often used in environments dealing with corrosive or wet dust.

The design of the filter is also crucial to its performance:

Pleated Design: Pleated filters increase the surface area, offering better dust-capturing capabilities, thus improving efficiency and extending the replacement cycle.

Bag Design: Ideal for high-flow, high-load environments, these filters can efficiently collect large amounts of dust.

Cartridge Design: Compact and efficient, cartridge filters are suitable for small spaces or precise filtration needs.

Choosing the right material and design significantly enhances the dust collection system's efficiency and longevity.

4. Filter Cleaning and Maintenance

Over time, dust accumulates on the filter, which increases resistance and decreases airflow and filtration efficiency. Therefore, regular cleaning and maintenance are essential. Various cleaning methods are used depending on the type of dust collection system:

Reverse Air Cleaning: This method reverses the airflow to blow dust off the filters. It is commonly used in high-efficiency systems like bag filters.

Shaking or Beating: Some dust collection systems use mechanical shaking or beating to loosen the accumulated dust, making it easier to remove. This method is effective for dry dust that doesn't easily adhere to the filter.

Pulse Jet Cleaning: Compressed air is released in short, quick bursts to clean the filter. The powerful air pulses dislodge fine dust particles, maintaining filter performance.

Regular cleaning and maintenance not only improve filter performance but also prevent system failures due to clogged filters. The cleaning schedule depends on factors such as dust concentration in the environment and the type of filter used.

5. Efficiency and Air Quality

High-efficiency filters, such as HEPA filters, can remove 99.97% of particles as small as 0.3 microns, making them ideal for environments where air quality is crucial. These filters are used in medical facilities, laboratories, food production areas, and other places where strict air quality standards are necessary. In addition to HEPA filters, certain industrial applications may require specialized filters tailored to specific types of dust.

For larger industrial environments, dust collection systems aim to reduce workers' exposure to hazardous materials, preventing respiratory issues and other health problems. Moreover, a good dust collection system can minimize dust buildup, protect equipment from wear, and extend the lifespan of machinery, thus reducing maintenance costs.

These systems are vital components of any industrial environment that requires dust control. Understanding how they work and how to maintain them helps ensure smooth operations, protects equipment, and ensures the safety and health of employees.

English

English Español

Español 日本語

日本語