1. Physical Form

Granular Activated Carbon (GAC):

Granular activated carbon (GAC) consists of larger, irregular particles, typically ranging in diameter from 0.2 mm to 5 mm. The shape and size of each particle can vary, with some particles appearing fragmented or irregular. These larger particles allow for longer contact times between the water or air and the carbon, making GAC ideal for continuous filtration processes where slower filtration is needed. The larger particle size also provides more physical stability, preventing the carbon from breaking apart during use, which is crucial for maintaining the filtration system's integrity.

The manufacturing process of GAC generally involves two main steps: carbonization and activation. First, the raw material (such as wood, coal, or coconut shells) is heated at high temperatures to remove most of the organic components, followed by activation with steam or carbon dioxide to create a porous structure with a large surface area. The resulting granular carbon retains these characteristics, with a larger surface area that enhances its adsorption properties, making it effective at adsorbing contaminants over longer periods.

Due to its larger particle size, GAC is best used for applications requiring longer contact times, such as municipal water treatment or air purification systems. Its physical structure makes it more resistant to clogging and allows it to operate effectively for extended periods, which is why it is often chosen for long-term or continuous filtration processes.

Powdered Activated Carbon (PAC):

Powdered activated carbon (PAC) consists of much smaller, fine particles, typically less than 0.1 mm in diameter. The fine particles have a higher surface area compared to GAC, which allows PAC to adsorb contaminants quickly. However, this small particle size also means that PAC can clog filtration systems more easily and is typically used in batch processes where the carbon is added to the water or air and then removed after a short period.

The manufacturing process of PAC is similar to that of GAC, involving carbonization and activation, but PAC particles are much finer, leading to a higher surface area per unit volume. This high surface area gives PAC the ability to adsorb a larger quantity of contaminants in a shorter time, making it ideal for rapid adsorption in situations where quick removal of pollutants is needed.

Due to the fine nature of its particles, PAC is more effective at quickly capturing contaminants, which makes it useful for emergency or temporary filtration needs. However, the fine particles also mean that PAC is not suitable for continuous use or for long-term filtration systems, as the particles are difficult to regenerate or reuse effectively.

2. Surface Area and Adsorption Efficiency

Granular Activated Carbon (GAC):

While GAC has a relatively large surface area, it is lower per unit of volume compared to PAC. The larger particle size of GAC provides a longer contact time with the water or air, which is essential for efficient adsorption of pollutants over extended periods. GAC is ideal for processes where contaminants are present in lower concentrations and require prolonged exposure to the carbon for effective removal.

In applications such as water treatment and air purification, GAC is typically placed in a column or bed, through which water or air flows at a controlled rate. As the fluid passes through the GAC bed, contaminants gradually adhere to the carbon particles' surface, until the adsorption capacity of the carbon is exhausted. The extended contact time allows GAC to remove a broad spectrum of pollutants, including chlorine, volatile organic compounds (VOCs), and other dissolved chemicals.

While GAC is efficient for continuous filtration processes, its adsorption capacity is not as high as PAC in situations requiring rapid removal of contaminants. For example, GAC may not be as effective at removing small molecules or pollutants that require faster adsorption, as the larger particles do not provide the same immediate contact with contaminants.

Powdered Activated Carbon (PAC):

PAC has a significantly higher surface area per unit of volume compared to GAC, meaning it has a greater ability to adsorb pollutants in a shorter amount of time. This makes PAC highly effective for situations where quick removal of contaminants is essential, such as in wastewater treatment or in emergency situations where contaminants are at high concentrations and need to be removed rapidly.

The high surface area of PAC allows it to adsorb contaminants at a much faster rate than GAC, making it ideal for batch processes or situations where contaminants must be removed quickly. For example, PAC is often used for the rapid removal of chlorine, colorants, and organic compounds in drinking water and wastewater treatment. In these cases, PAC can treat large volumes of water in a short amount of time.

While PAC is more efficient in terms of rapid adsorption, its fine particle size also means that it can clog filtration systems more easily. This creates challenges in terms of filtration and regeneration. Additionally, because PAC is typically not reused, it must be replaced frequently, which can increase operational costs.

3. Applications

Granular Activated Carbon (GAC):

GAC is widely used in continuous filtration systems, particularly in water treatment and air purification applications, where it is used for long-term filtration. Common applications include:

Drinking Water Treatment: GAC is commonly used in municipal water treatment plants to remove organic contaminants, chlorine, tastes, odors, and some toxic substances. Its large particle size allows for slower, more controlled filtration, which is important for treating large volumes of water.

Wastewater Treatment: GAC is used in industrial wastewater treatment plants to remove dissolved organic compounds, heavy metals, and other contaminants. In these systems, GAC is typically placed in fixed or fluidized beds through which the wastewater flows, ensuring efficient adsorption over an extended period.

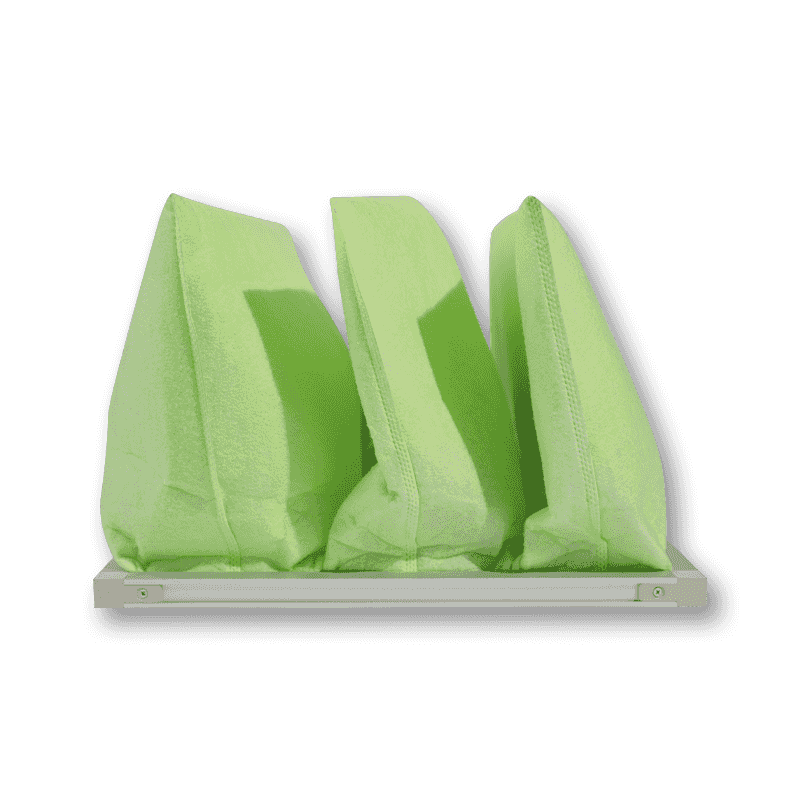

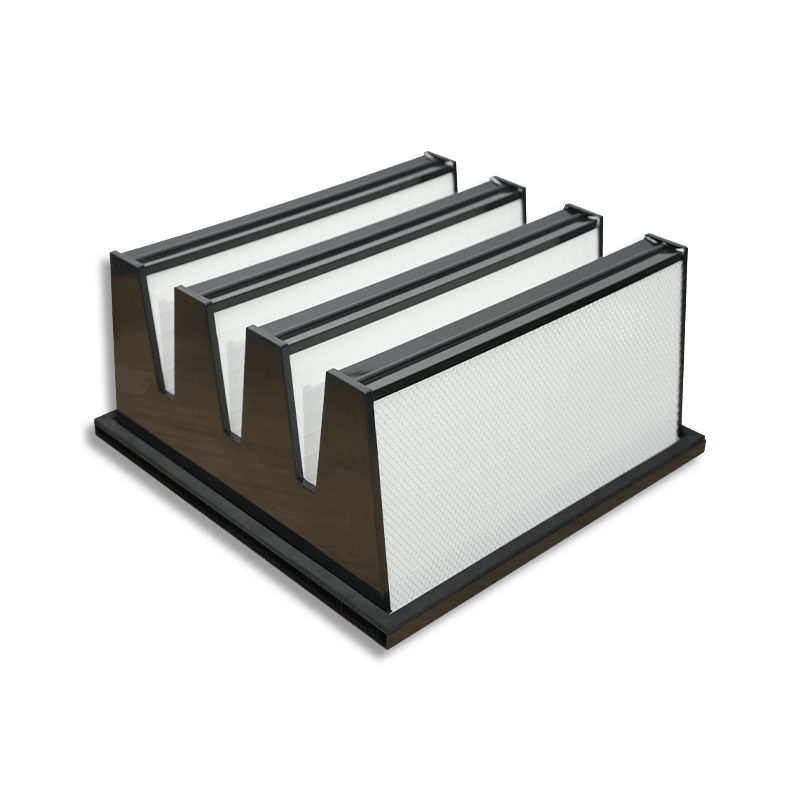

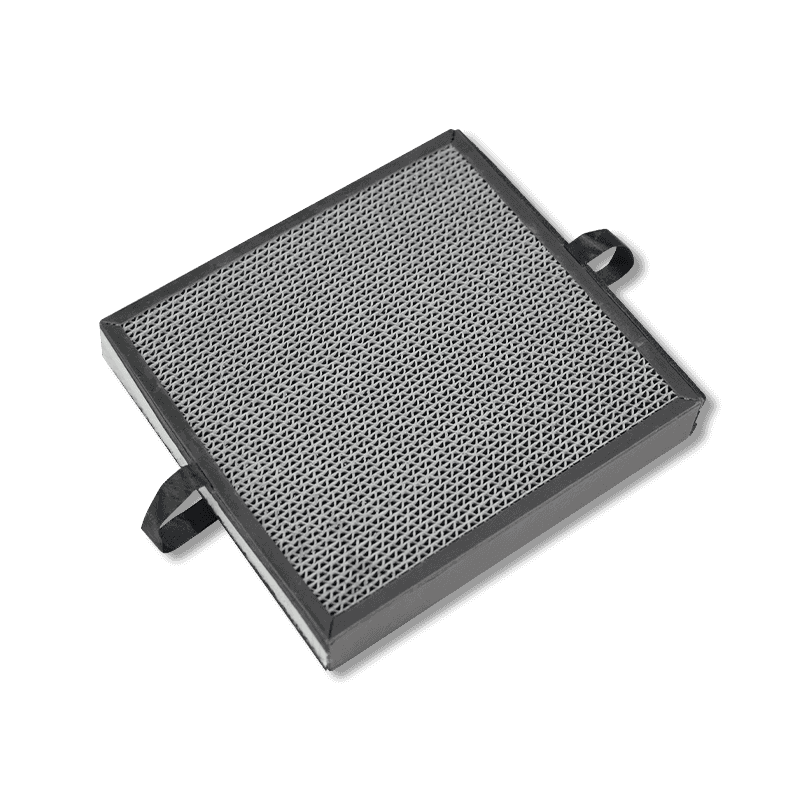

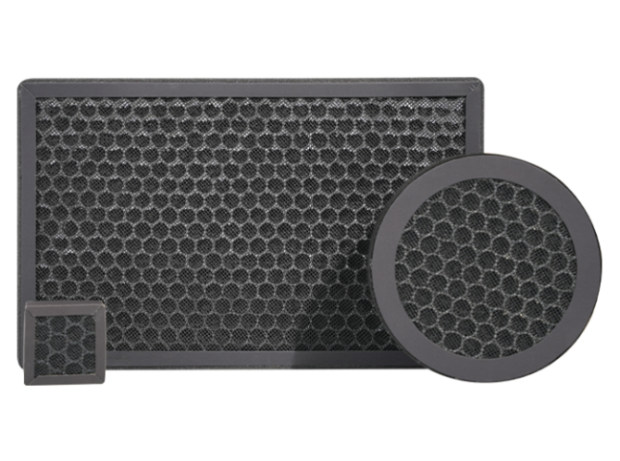

Air Purification: GAC is widely used in air filtration systems to remove volatile organic compounds (VOCs), odors, and chemical pollutants from industrial exhaust air, as well as in household air purifiers. It is particularly effective in removing odorous substances and harmful gases from the air.

The primary advantage of GAC is its longevity and ability to be regenerated, which makes it ideal for continuous filtration systems where a longer contact time is required for effective pollutant removal. It is commonly used in large-scale systems where long-term operation and cost-effectiveness are important.

Powdered Activated Carbon (PAC):

PAC is typically used in batch processes or for applications requiring rapid pollutant removal. Common applications include:

Drinking Water and Wastewater Treatment: PAC is often added to water or wastewater as a flocculant to remove organic compounds, colorants, chlorine, and odors. After the PAC is mixed with the water and adsorbs the contaminants, it is typically removed through sedimentation or filtration.

Food and Beverage Industry: PAC is used in food processing, particularly in beverage production, to remove colorants, impurities, and odors. It is commonly used in beer, juice, and soft drink production to ensure purity and clarity.

Industrial Gas Treatment: PAC is also used in industrial gas treatment applications to remove VOCs, gases, and odors from air emissions. It is particularly useful in applications where there is a need to treat large volumes of air in a short time.

Due to its fine particle size and high adsorption efficiency, PAC is ideal for batch treatments or emergency situations. It can quickly absorb large amounts of contaminants, but it is not suitable for continuous use because the fine particles are difficult to regenerate and must be replaced frequently.

English

English Español

Español 日本語

日本語