In modern environmental protection and health sectors, activated carbon has emerged as an indispensable filtration material, revolutionizing the way we address water treatment, air purification, and industrial waste management. Often hailed as the "magnetic king" of the filtration industry, activated carbon’s exceptional filtering performance, combined with its unique physical and chemical properties, makes it a versatile and powerful tool. With its “magnetic” adsorption ability, activated carbon efficiently captures harmful substances from both air and water, improving environmental quality and public health.

The Science Behind Activated Carbon: From "Carbon" to "Activated"

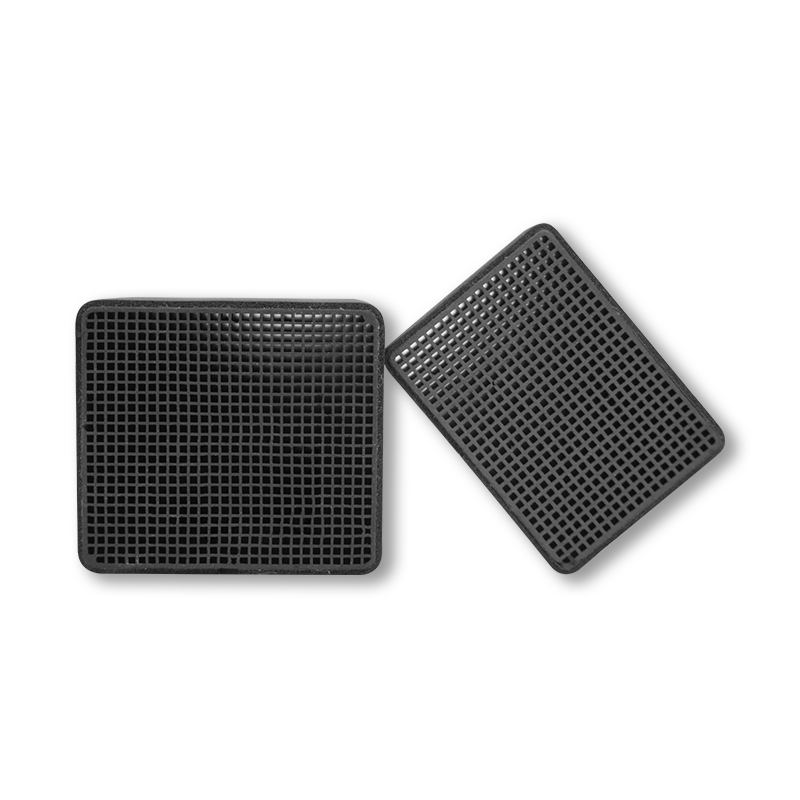

Activated carbon, also known as activated charcoal, is derived from carbon-rich materials like wood, coconut shells, or coal. These materials are subjected to high heat or chemical processes that activate them, turning them into a highly porous substance with a vast surface area. This activation process results in a material that is capable of adsorbing a wide range of contaminants. The crucial feature of activated carbon is its "adsorptive" capability, which differs from the traditional "absorption" process. Adsorption involves contaminants sticking to the surface of the material, while absorption involves the contaminants being absorbed into the material itself.

The production process of activated carbon typically involves heating raw carbon materials in the presence of gases, which creates a network of tiny pores within the carbon. These pores significantly increase the surface area of the carbon, allowing it to capture more contaminants. In fact, just one gram of activated carbon can have a surface area of up to 3,000 square meters, providing ample space for the adsorption of a variety of pollutants.

Why does the structure of activated carbon impact its filtration ability?

The key to activated carbon's effectiveness lies in its microscopic porous structure. These tiny pores serve as trapping mechanisms for pollutants, allowing the carbon to "catch" contaminants as they pass through. The greater the surface area of activated carbon, the more pollutants it can adsorb. These pores come in different sizes and configurations, which impact the carbon's ability to capture different types of pollutants. High-quality activated carbon tends to have more and finer pores, which makes it more efficient at filtering a broad spectrum of contaminants.

Activated carbon has surface chemistry that enhances its ability to adsorb certain types of contaminants. For instance, it can attract and hold onto organic compounds, chemicals, heavy metals, and even gases, through both physical and chemical forces. This capability makes activated carbon highly versatile, as it can filter a wide range of substances, from volatile organic compounds (VOCs) to chlorine, pesticides, and even pharmaceuticals.

“Magnetic” Filtration: Activated Carbon’s Powerful Adsorptive Ability

Why is activated carbon called the “magnetic king” of filtration? The term “magnetic” doesn’t refer to a literal magnetic force, but rather to the material’s ability to attract and hold onto a wide range of contaminants, much like a magnet attracts metal objects. This "magnetic" behavior is due to the electrostatic forces on the surface of activated carbon, which draw in pollutants from the surrounding environment.

In Water Treatment:

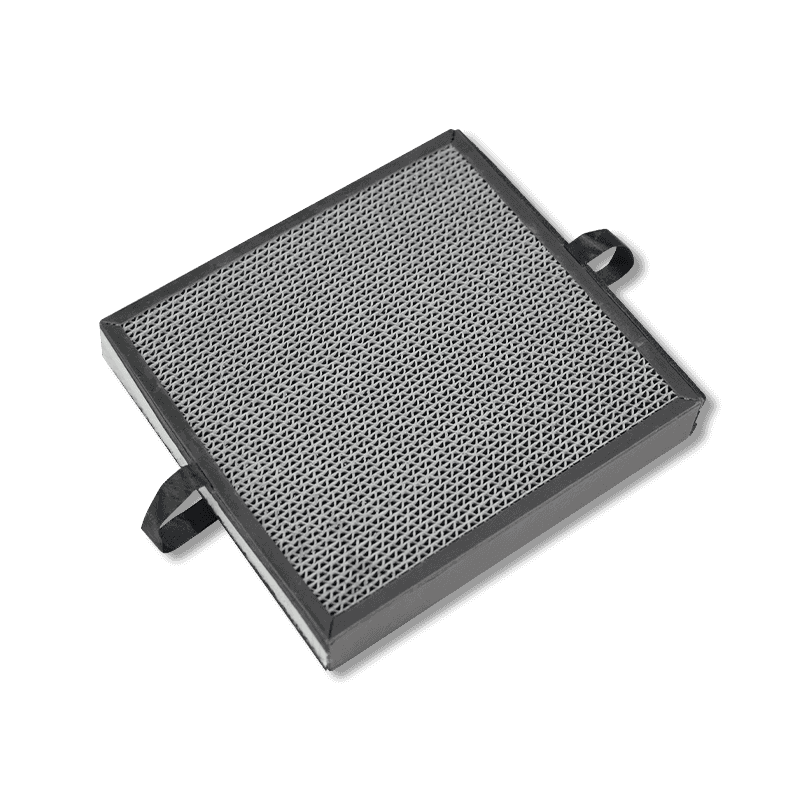

One of the most common applications of activated carbon is in water purification. Water often contains various pollutants such as chlorine, volatile organic compounds (VOCs), pesticides, heavy metals, and undesirable odors. Activated carbon filters are widely used in both residential and industrial water treatment systems to remove these contaminants. It does so by adsorbing the harmful molecules onto its vast surface area. Activated carbon is particularly effective at removing chlorine, which is commonly used in municipal water supplies to disinfect, but which can leave an unpleasant taste and odor. It also removes pesticides and heavy metals that can be harmful to human health.

Activated carbon's effectiveness is also seen in its ability to eliminate other contaminants, such as industrial solvents and pharmaceuticals that may enter water supplies. Activated carbon is not just used in household water filters but also in large-scale water treatment facilities to improve the quality of drinking water.

In Air Purification:

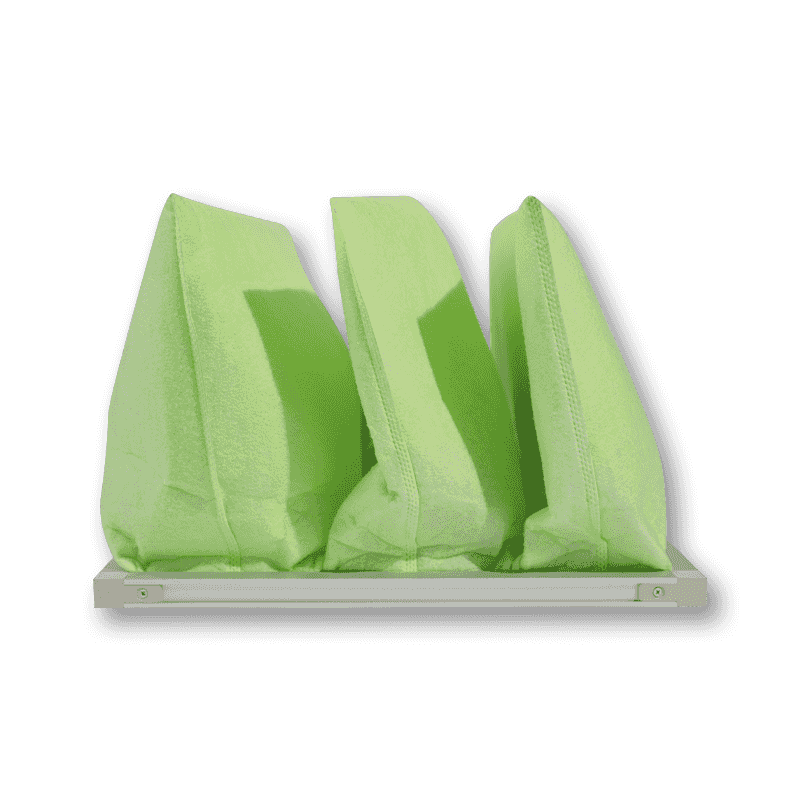

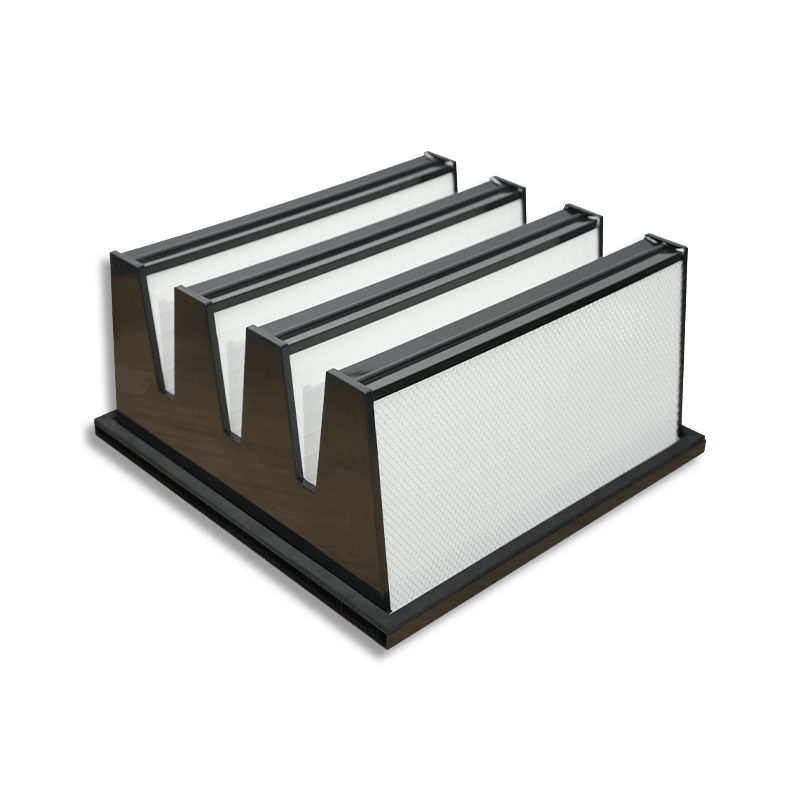

Airborne pollutants, including volatile organic compounds (VOCs), nitrogen dioxide (NO₂), ozone (O₃), and particulate matter (PM2.5), present a growing risk to public health and the environment. Activated carbon’s filtration properties are just as effective when it comes to air purification. In residential, commercial, and industrial settings, air purifiers that use activated carbon filters can effectively trap and neutralize these harmful substances.

Activated carbon filters work by attracting and adsorbing pollutants, including gases, vapors, and particles. Many air purifiers on the market today rely on activated carbon as a core component for removing odors, toxic gases, and smoke. For instance, activated carbon is essential in dealing with indoor air pollution, where volatile organic compounds from paints, cleaners, and furnishings can contribute to poor air quality.

Beyond Gaseous Pollutants:

Activated carbon’s filtration capabilities extend beyond just gases. Its porous structure also allows it to capture particles suspended in the air, such as dust, pollen, and smoke. In areas affected by high levels of air pollution, activated carbon filters are used not only for reducing harmful gases but also for minimizing particulate pollution. The ability to purify the air of allergens and particles like PM2.5 is critical for improving indoor air quality, especially in urban environments.

Activated Carbon’s Critical Role in Environmental Remediation

Beyond its well-known applications in water and air filtration, activated carbon plays a crucial role in environmental remediation. From industrial waste management to soil decontamination, activated carbon is used to address various forms of pollution. Its ability to adsorb both organic and inorganic contaminants makes it a powerful tool in environmental protection.

Wastewater Treatment:

In industrial wastewater treatment, activated carbon is widely used to remove organic pollutants, color, and toxic substances from effluents. Industries like pharmaceuticals, petrochemicals, and textiles generate wastewater that contains a variety of harmful chemicals and toxins. Activated carbon’s vast surface area allows it to adsorb these pollutants, preventing them from being released into the environment. This makes activated carbon an essential material for industries looking to minimize the environmental impact of their operations.

Activated carbon is often used in conjunction with other water treatment processes, such as filtration and chemical treatments, to ensure that water meets regulatory standards for discharge into water bodies. It is also employed in reverse osmosis systems to remove specific contaminants that other filtration methods might miss.

Soil Remediation:

Activated carbon has also proven effective in soil remediation, particularly in cases of oil spills, pesticide contamination, and heavy metal pollution. When applied to contaminated soil, activated carbon can adsorb harmful substances, preventing them from leaching into groundwater or spreading further. The use of activated carbon in soil remediation is particularly valuable for sites that require clean-up of hazardous materials, as it provides an efficient and cost-effective solution.

By applying activated carbon to polluted soil, not only can contaminants be captured, but their potential for harmful effects on plants, animals, and ecosystems is minimized. Over time, activated carbon helps to restore soil quality, enabling it to support plant growth and contribute to ecological balance.

Air Pollution Control:

In industries with high emissions, such as petrochemical refineries, power plants, and metal smelting operations, activated carbon plays a pivotal role in controlling air pollution. Activated carbon adsorbs harmful gases like sulfur dioxide (SO₂), hydrogen sulfide (H₂S), and volatile organic compounds (VOCs), which, if left untreated, would contribute to air pollution. It is commonly used in both stationary pollution control systems and in the filtration of exhaust gases.

Activated carbon filters are also used in applications such as smoke stack scrubbing systems, where they prevent the release of toxic compounds into the atmosphere. As air pollution regulations become more stringent, the demand for activated carbon in industrial pollution control systems continues to grow.

The Future of Activated Carbon: Continued Innovation and Sustainability

As global environmental challenges continue to evolve, the demand for activated carbon in filtration and remediation applications is only expected to increase. Technological advancements are driving innovation in the production and use of activated carbon, with new materials and processes being developed to enhance its performance.

Sustainability and Regeneration:

One key area of innovation is the development of more sustainable activated carbon materials. Traditionally, activated carbon is produced from fossil fuels such as coal or non-renewable wood. However, there is growing interest in creating activated carbon from renewable resources, such as coconut shells, bamboo, and agricultural by-products. These materials not only reduce the environmental impact of carbon production but also offer comparable or even superior filtration capabilities.

As the cost of raw materials rises, there has been a push towards recycling and regenerating spent activated carbon. The regeneration process involves cleaning used activated carbon so that it can be reused, which helps reduce the amount of waste generated. Researchers are also exploring ways to make this regeneration process more efficient, ensuring that spent carbon can be revitalized without losing its adsorptive capacity.

English

English Español

Español 日本語

日本語