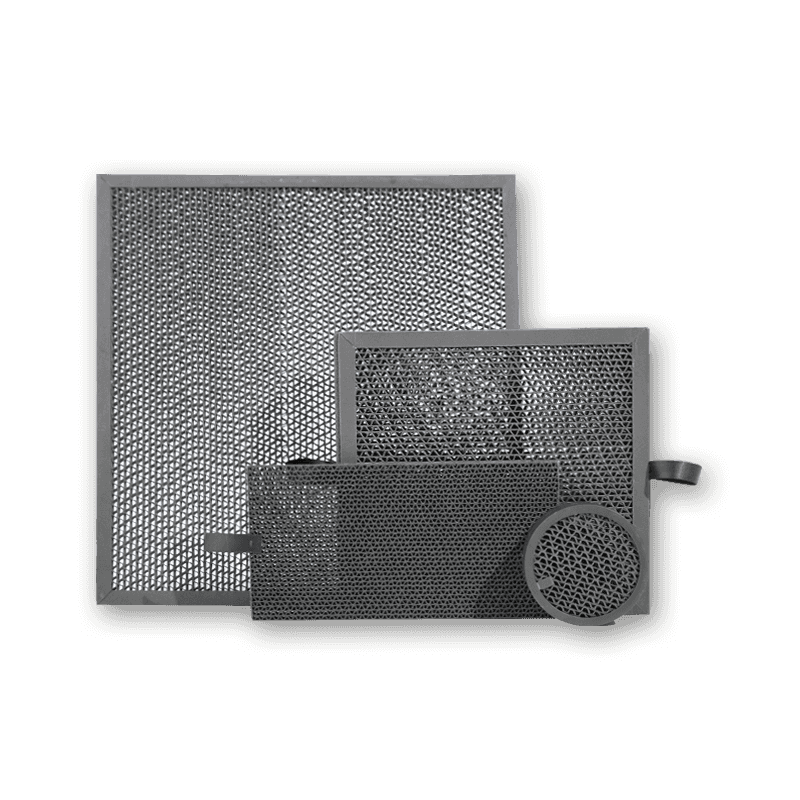

1. Introduction to Activated Carbon Filters

Activated carbon (AC) filters have been a core technology in filtration processes for over a century, providing crucial solutions in fields ranging from environmental protection to industrial applications. Activated carbon is produced by heating carbon-rich materials such as coconut shells, coal, or wood in the presence of a limited amount of oxygen, which leads to the development of highly porous structures. This "activation" process opens up millions of tiny pores within the material, providing an extremely high surface area—often ranging between 500 and 1500 m² per gram. This enormous surface area, combined with the material's ability to attract and trap molecules, makes activated carbon ideal for adsorption, the process by which contaminants are attracted and held on the surface of the material.

The broad application of activated carbon is largely due to its high capacity for adsorbing a wide variety of substances, such as organic compounds, gases, and pollutants. AC is used in diverse fields such as:

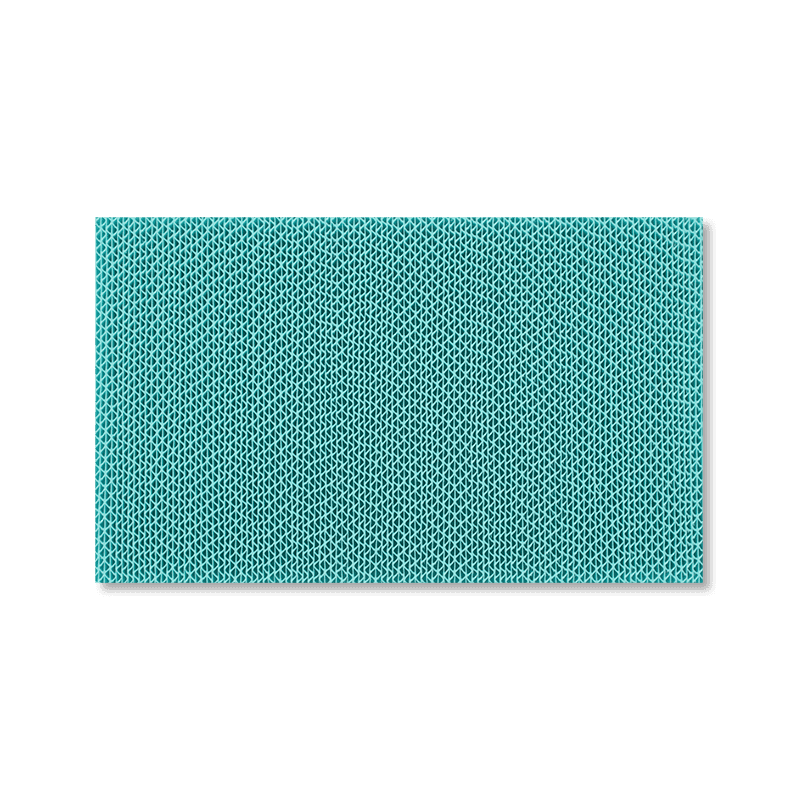

Water Treatment: In municipal and industrial water treatment systems, activated carbon removes harmful substances like chlorine, pesticides, heavy metals, and volatile organic compounds (VOCs). Granular activated carbon (GAC) filters and powdered activated carbon (PAC) are common types used in water filtration systems.

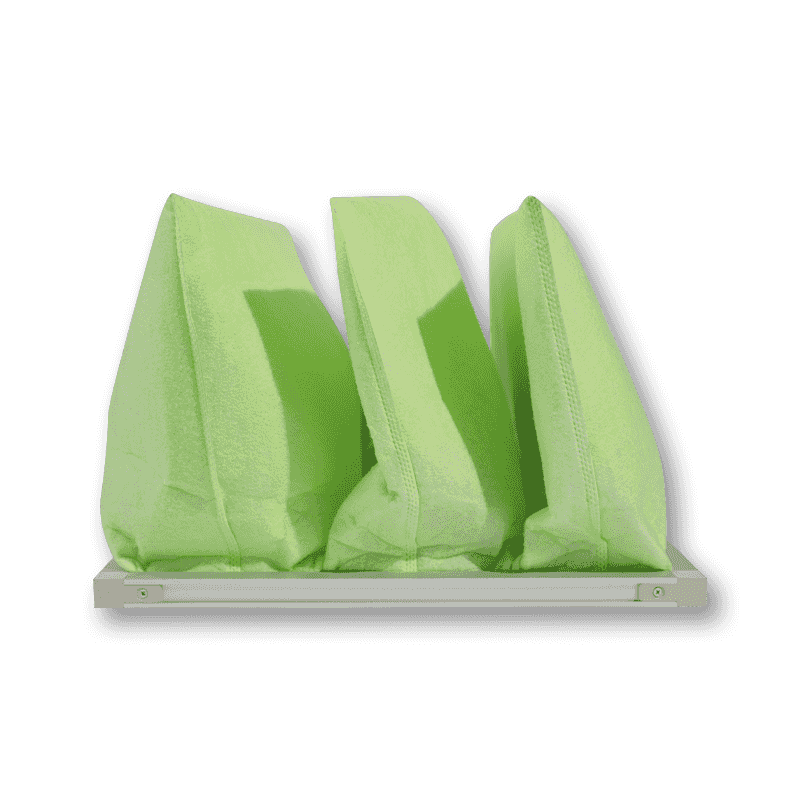

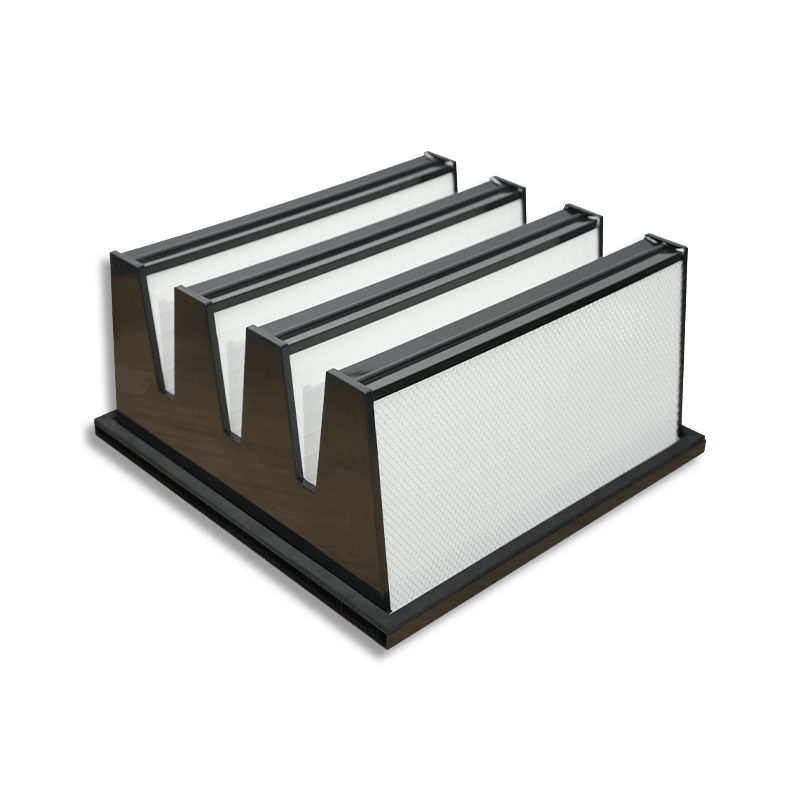

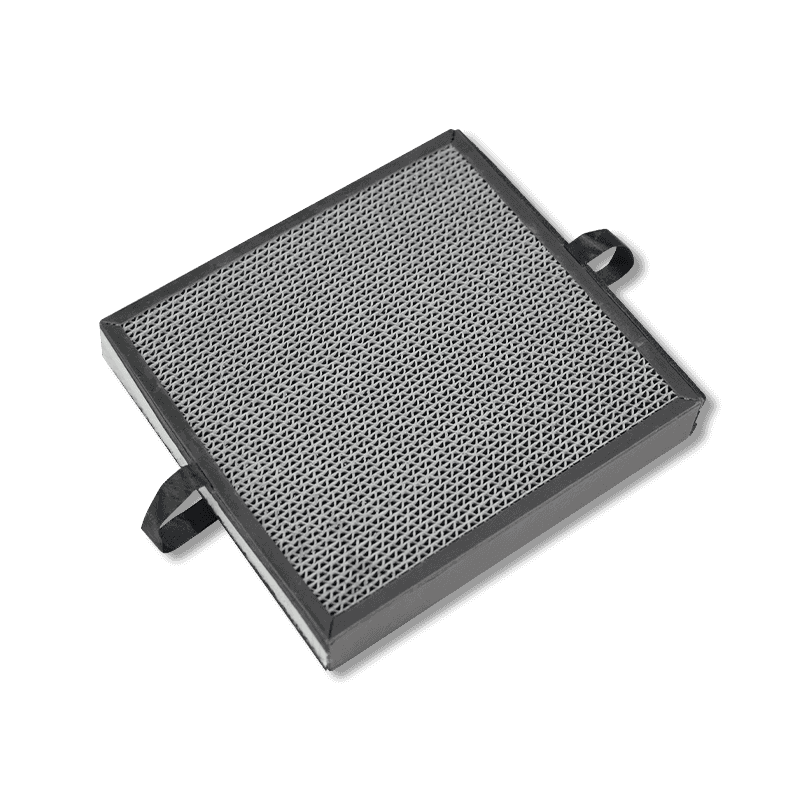

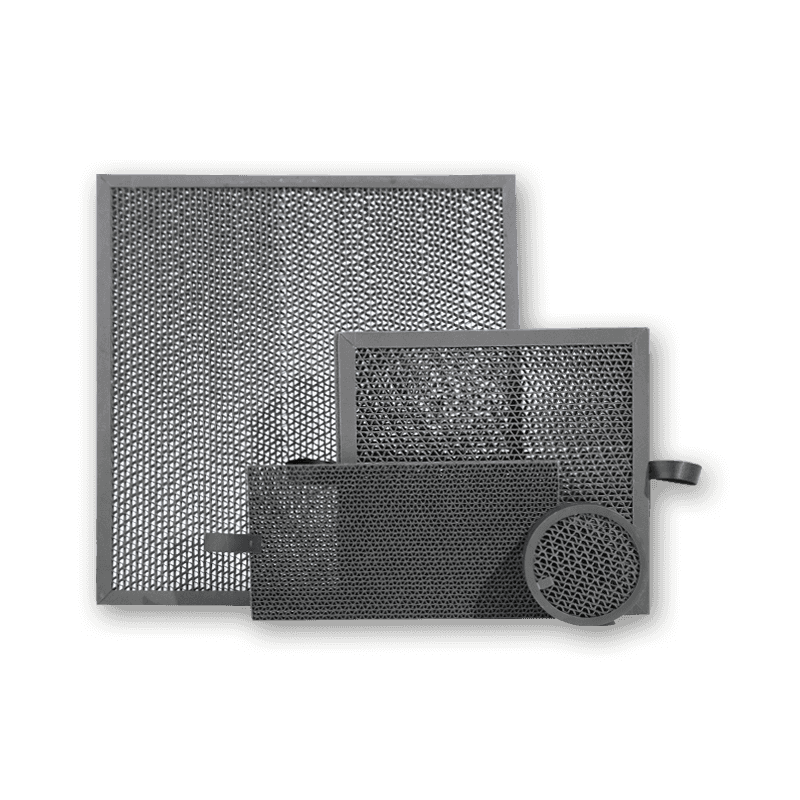

Air Purification: Activated carbon filters are widely used in air filtration systems to remove pollutants such as volatile organic compounds (VOCs), formaldehyde, ammonia, and cigarette smoke. These filters play a crucial role in improving air quality in both residential and commercial buildings.

Industrial Processes: In industrial applications, activated carbon is used in solvent recovery, gas purification, and chemical manufacturing processes to remove contaminants from gases or liquids.

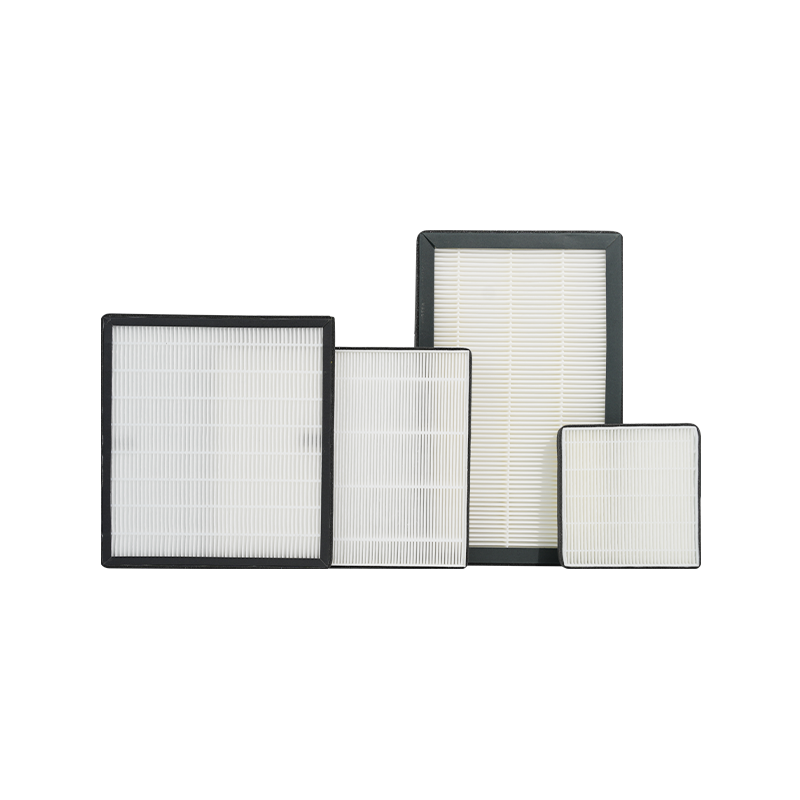

2. Enhanced Performance of Activated Carbon Filters

To improve the efficiency of activated carbon filters, scientists and engineers have developed several methods to enhance the material’s adsorption capacity, selectivity, and stability. These modification techniques allow activated carbon to become more specialized, making it capable of addressing a broader range of contaminants more effectively.

2.1. Surface Functionalization

Surface functionalization is a technique used to introduce specific chemical groups onto the surface of activated carbon. These functional groups can increase the material's affinity for particular contaminants, enhancing its performance in targeted applications. The key methods of surface modification include:

Oxidation Treatment: By exposing activated carbon to oxidizing agents like nitric acid or ozone, oxygen-containing functional groups (such as carboxyl, hydroxyl, and carbonyl groups) are introduced onto the carbon surface. These functional groups increase the material’s ability to adsorb polar compounds, such as organic molecules, metals, and certain gases.

Amination: Introducing amine groups onto the surface of activated carbon enhances its ability to adsorb acidic gases like carbon dioxide (CO2) and hydrogen sulfide (H2S), as well as certain organic pollutants. This modification is particularly useful for air filtration systems where the removal of acidic gases is required.

Metal Ion Loading: Incorporating metal ions such as silver, copper, and iron onto the activated carbon surface provides additional active sites that enhance its capacity to adsorb specific contaminants. Metal-modified activated carbon is highly effective for applications such as removing VOCs, dyes, and heavy metals from water.

Surface functionalization enables activated carbon to be tailored for specialized applications, improving its selectivity for particular contaminants and increasing its overall efficiency.

2.2. Integration of Nanotechnology

Nanotechnology has brought significant advancements to the field of activated carbon filtration. By incorporating nanomaterials into activated carbon, the material’s surface area, mechanical strength, and overall adsorption capacity can be enhanced, leading to more efficient filtration. Some notable nanotechnological approaches include:

Carbon Nanotubes (CNTs): When carbon nanotubes are integrated with activated carbon, the material’s surface area and mechanical properties are enhanced. CNTs offer unique structural advantages, including increased surface area and the ability to adsorb a wide range of pollutants, such as heavy metals and organic compounds. CNTs can also improve the material's structural integrity, making it more durable under harsh conditions.

Graphene Oxide (GO): Graphene oxide is another nanomaterial that, when incorporated into activated carbon, enhances its adsorption capabilities and overall surface reactivity. GO-modified activated carbon is particularly useful for adsorbing gas-phase pollutants, including VOCs, CO2, and methane. The material’s additional surface functionalities also improve its resistance to fouling, ensuring long-term performance.

Nanoparticles of Metals: Metal nanoparticles, such as silver, gold, or copper, can be loaded onto activated carbon to provide enhanced catalytic and adsorptive properties. These nanoparticles can improve the material’s ability to adsorb specific pollutants, such as sulfur compounds, and can also introduce antimicrobial properties, making the filters useful in both air and water purification.

By incorporating nanomaterials, activated carbon can be optimized for a range of specialized filtration applications, offering improved efficiency and sustainability.

2.3. Composite Materials

Composite materials combine activated carbon with other substances to enhance its performance. These composites are particularly useful for applications requiring specific removal capabilities, such as gas separation or selective adsorption. Some of the key composite materials include:

Zeolite-Activated Carbon Composites: Zeolites are microporous minerals known for their ability to exchange ions and adsorb specific gases. By combining zeolites with activated carbon, the material’s ability to remove certain pollutants, such as ammonia or hydrogen sulfide, is enhanced. Zeolite-activated carbon composites are often used in industrial applications and air purification systems.

Metal-Organic Framework (MOF)-Activated Carbon Composites: MOFs are highly porous materials with tunable pore structures and exceptionally high surface areas. When combined with activated carbon, MOFs enhance the material’s ability to adsorb gases such as CO2, methane, and hydrogen. These composites are ideal for applications in carbon capture and gas separation, where high adsorption capacity is essential.

Composites allow activated carbon to be tailored for specific removal tasks, making them particularly useful in industries that deal with complex mixtures of pollutants.

2.4. Advanced Treatment Techniques

In addition to traditional modification methods, advanced treatment techniques have been developed to further enhance the performance of activated carbon. Two such techniques—microwave-assisted treatment and plasma treatment—offer promising improvements in carbon filtration:

Microwave-Assisted Treatment: By subjecting activated carbon to microwave radiation, the material’s pore structure and surface area can be optimized. The rapid heating process enhances the adsorption capacity of activated carbon, making it more effective at removing a wide range of pollutants, particularly VOCs and small organic molecules. This method can also improve the material's regeneration potential, reducing the need for frequent replacement.

Plasma Treatment: Plasma treatment involves exposing activated carbon to ionized gases, which modifies the surface chemistry of the material. Plasma treatment can introduce functional groups that improve the carbon's affinity for specific contaminants, making it more selective and efficient in adsorption. This technique also improves the material’s stability, allowing it to maintain its performance over longer periods.

Both microwave and plasma treatment offer innovative ways to enhance the surface properties of activated carbon, increasing its effectiveness in filtration applications and contributing to its sustainability.

3. Emerging Applications of Modified Activated Carbon Filters

The advancement of modification technologies has led to the expansion of activated carbon’s applications across various industries. These enhanced materials are increasingly being used in specialized applications where traditional activated carbon may not suffice. Some notable emerging applications include:

3.1. Water Purification

Modified activated carbon filters are playing an increasingly important role in addressing emerging water contaminants such as pharmaceuticals, endocrine-disrupting chemicals, and microplastics. Traditional activated carbon is effective in removing chlorine, VOCs, and heavy metals, but modified versions are being tailored to adsorb more persistent and complex pollutants. For example, activated carbon functionalized with amine groups can remove organic pollutants more efficiently, while composites with zeolites or MOFs can target specific contaminants, such as ammonia or pharmaceuticals. These advanced materials offer a more comprehensive solution to modern water purification challenges.

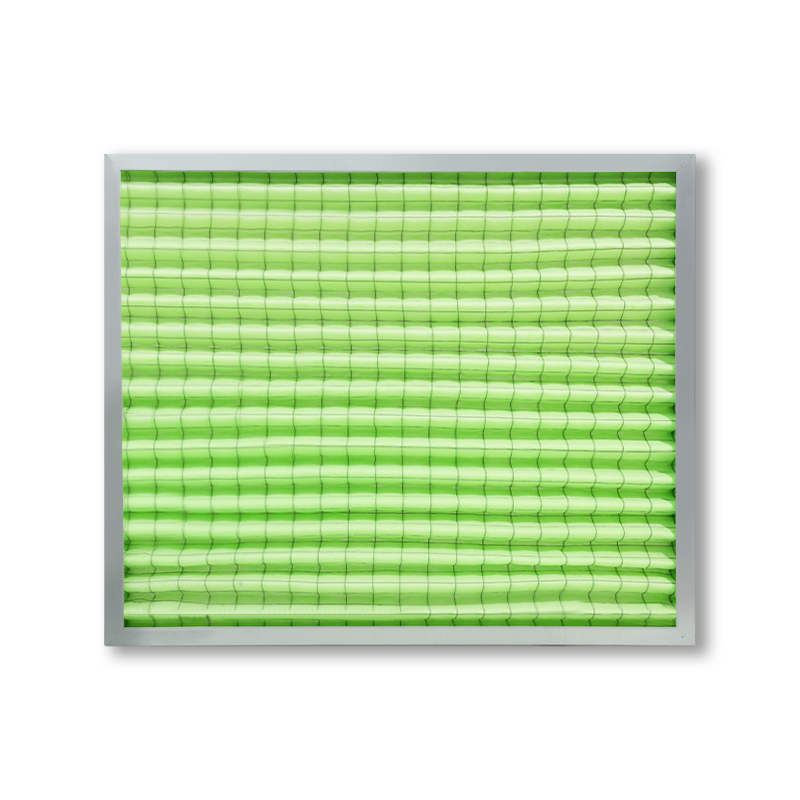

3.2. Air Quality Improvement

The rise of urbanization and industrialization has made air pollution a significant health concern. Modified activated carbon filters are being designed to target specific pollutants such as nitrogen oxides (NOx), sulfur dioxide (SO2), and VOCs. These filters are used in a range of applications, from industrial exhaust systems to residential air purifiers. By tailoring the surface properties and pore structure, these filters can more effectively remove harmful gases, improving indoor and outdoor air quality. The addition of antimicrobial properties through metal nanoparticle loading is enhancing the ability of activated carbon to remove airborne pathogens, making it valuable in healthcare settings.

3.3. Carbon Capture and Sequestration

The growing concern over climate change has led to increased interest in carbon capture technologies. Modified activated carbon is being explored for its potential to capture and store carbon dioxide (CO2) emissions from industrial processes. Activated carbon composites with MOFs, in particular, are showing promise for CO2 adsorption due to their high surface area and tunable pore sizes. These materials offer a sustainable solution for reducing the environmental impact of fossil fuel-based industries and contribute to global efforts to mitigate climate change.

3.4. Industrial Wastewater Treatment

In industrial applications, wastewater often contains a variety of pollutants, including organic compounds, heavy metals, and other harmful chemicals. Modified activated carbon materials are being developed to efficiently remove these contaminants, offering a more targeted and effective approach to wastewater treatment. For example, composites with zeolites or MOFs are being used to remove specific pollutants, while activated carbon with enhanced adsorption capacity is helping to reduce the overall environmental impact of industrial wastewater discharges.

English

English Español

Español 日本語

日本語