Formaldehyde and TVOC gases are the main sources of pollution that affect indoor air quality, especially in confined spaces such as newly renovated places, commercial office buildings, and vehicle interiors. Traditional activated carbon materials mainly rely on physical adsorption and cannot completely decompose harmful gases. As the use time increases, the effect gradually weakens. Therefore, more and more air purification equipment manufacturers, fresh air system integrators, and vehicle purification module OEM companies have begun to use catalytic air filter materials to achieve gas decomposition and purification while ensuring filtration efficiency.

Lyusen Environmental Protection can provide a complete series of catalytic filter products and catalytic functional materials:

▶Click to view product details:

Principle analysis and performance comparison of cold catalyst and photocatalyst

Photocatalyst: Relying on light energy, releasing strong oxidizing ability, effectively decomposing a variety of harmful gases

Photocatalyst is a functional purification material that relies on light activation, mainly using nano-scale titanium dioxide (TiO₂) as the core component. When its surface is irradiated by ultraviolet (UV) or strong visible light, it will excite electron (e⁻) and hole (h⁺) pairs, and react with moisture and oxygen in the air to produce highly oxidizing hydroxyl radicals (·OH) and superoxide anions. These highly active free radicals can quickly decompose a variety of organic pollutants such as formaldehyde, benzene, TVOC, and ultimately convert them into harmless water and carbon dioxide to achieve thorough purification.

Photocatalyst materials are not consumed during the reaction process, and theoretically can be used for a long period of time and at high frequencies. In practical applications, their performance stability is excellent, and adsorption saturation or performance degradation is not likely to occur. This advantage is particularly prominent when used in combination with traditional filter materials (such as HEPA, activated carbon), which can significantly extend the filter replacement cycle and reduce subsequent maintenance costs.

However, it is worth noting that the catalytic reaction intensity of photocatalysts is heavily dependent on light source conditions. In insufficient light or in a closed pipe structure, its catalytic efficiency will drop significantly. Therefore, when integrating the product, additional consideration needs to be given to the layout of the UV light source, the uniformity of light, and the angle design of the filter. Nevertheless, for high-end purification equipment with lighting capabilities, photocatalysts are still a preferred technology that combines oxidation efficiency and sterilization capabilities.

For fresh air system integrators, the use of photocatalyst technology can significantly improve the system's purification capacity for complex organic pollution and increase product added value. However, during the project implementation phase, it is necessary to fully evaluate the lighting conditions of the target scene and the feasibility of the filter and light source coupling design to ensure the continued efficient operation of the photocatalyst.

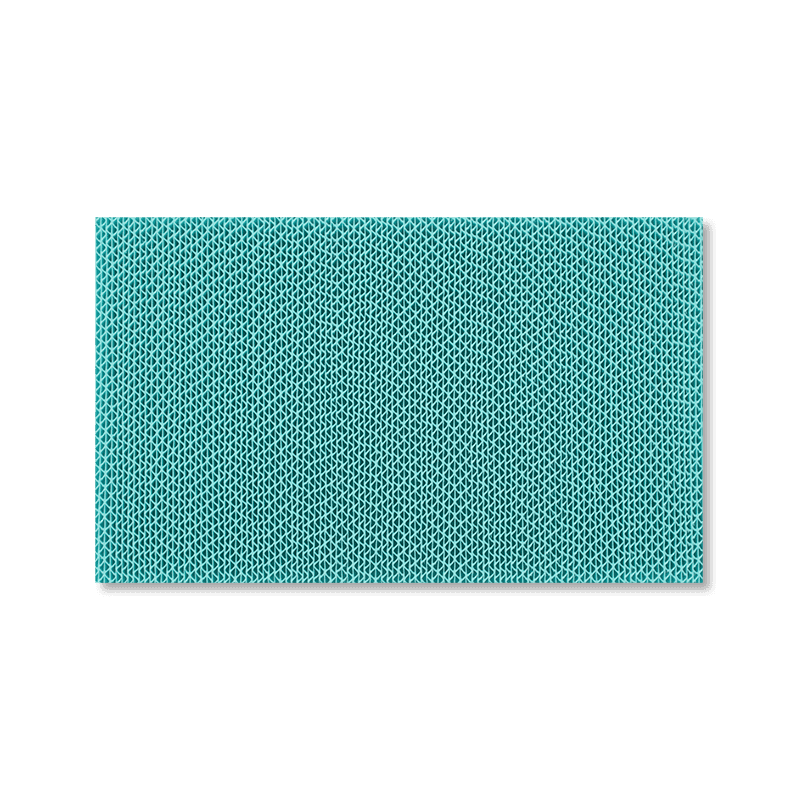

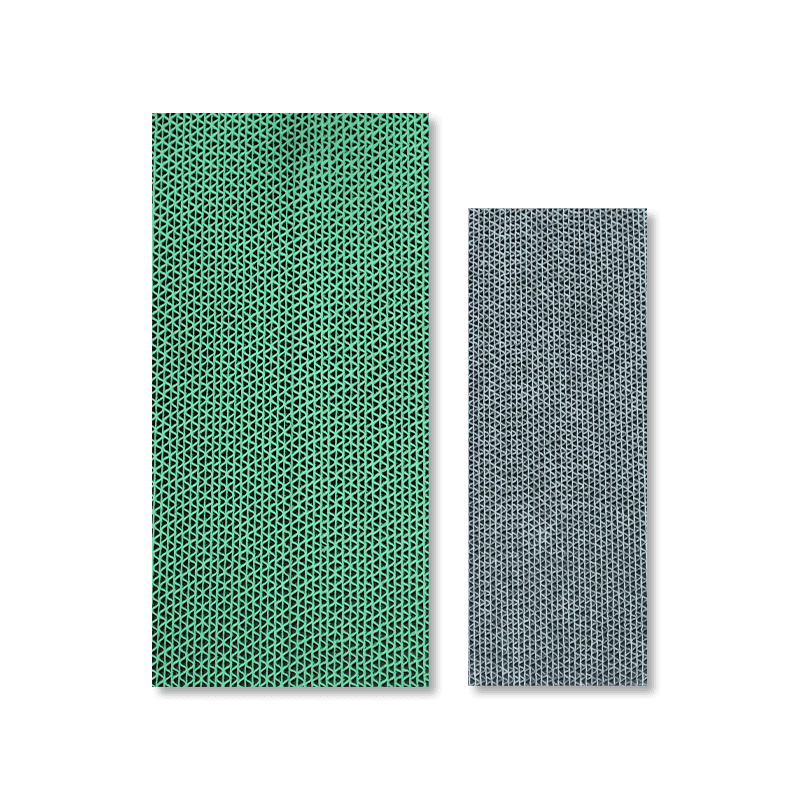

In view of this characteristic, the Paper-based Photocatalyst Filter Mesh we launched uses a paper-based material with high air permeability and high specific surface area as a carrier, and uses plasma coating technology to evenly load TiO₂ on the fiber surface, so that it can achieve a stable catalytic reaction under conventional UV-A or LED lighting. Its advantages such as light weight, easy cutting, and flexible structure make it very suitable for the integration of fresh air systems, wall-mounted air purifiers and other modular purification equipment.

Cold catalyst: Stable reaction at room temperature, taking into account energy efficiency and continuous purification

Cold catalyst is a functional material that can undergo catalytic reaction at room temperature or low temperature. Its main components are mostly transition metal or rare earth metal oxides (such as MnO₂, Fe₂O₃, CuO, etc.). Unlike photocatalysts, cold catalysts do not rely on any external light source or energy input, and are completely degraded by chemical reactions between the catalytic surface and polluted gas molecules in the air. This makes it a widely applicable purification module in fresh air systems, especially suitable for use in building environments with insufficient light or strict energy consumption control.

The main working mechanism of cold catalysts is to continuously capture pollutants such as formaldehyde, ammonia, benzene, TVOC, etc. in the air through chemical adsorption and surface catalytic reaction, and decompose them into CO₂ and H₂O. Unlike the problem of "ineffectiveness when full" of adsorption materials such as traditional activated carbon, cold catalysts will not be saturated during the reaction process, but can maintain continuous purification capabilities for a long time. This is of practical significance for dealing with the formaldehyde slow release process in new decoration environments that lasts for months or even years.

Cold catalyst filters usually have good stability and mechanical strength, and are not prone to performance fluctuations due to environmental factors such as humidity and temperature differences, which is particularly critical for continuous operation in commercial projects. Some high-quality cold catalyst materials can even be simply regenerated by hot air or cleaning, greatly extending the service life and further reducing the cost of subsequent maintenance.

The catalytic reaction activity of cold catalysts is slightly lower than that of photocatalysts, especially in short-term high-load environments, where the reaction rate is slower. If the target environmental pollutant concentration is high and the purification demand responds quickly, cold catalysts may require a larger surface area or work in conjunction with other functional materials to achieve the desired effect.

In the actual product landing process, cold catalysts are more suitable as stable purification materials under normal operation to maintain long-term air quality, reduce energy consumption, and extend the service life of filter materials. For fresh air system integrators, their extremely high compatibility and low maintenance costs make cold catalysts an important technical path for building economical or energy-saving purification systems.

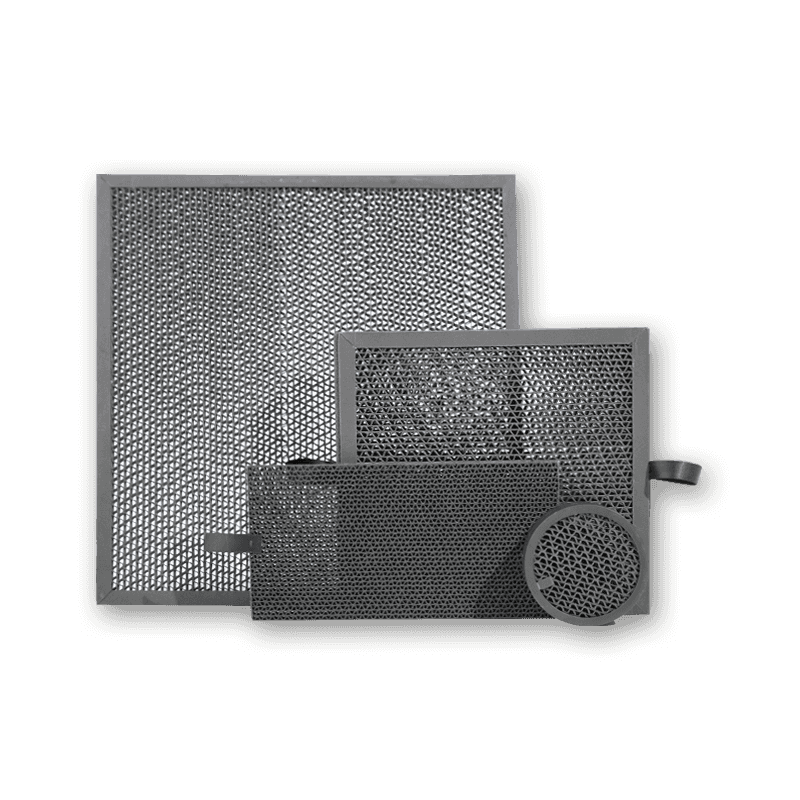

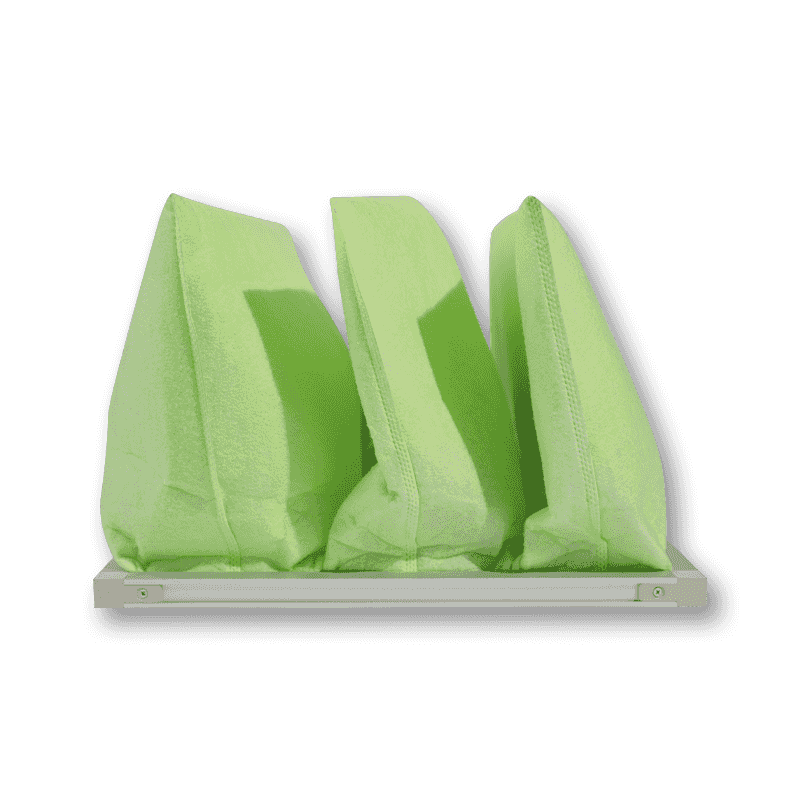

In response to the above needs, we launched Sponge Cold Catalyst Filter Mesh, a high-performance filter material solution designed for fresh air systems, air purification equipment and commercial building air conditioning systems. This product uses an open porous PU substrate, which gives it a very high specific surface area and excellent air flow permeability. At the same time, it is evenly loaded with cold catalyst active ingredients to achieve continuous catalytic decomposition of harmful gases such as formaldehyde, TVOC, ammonia, and sulfides under normal temperature conditions. The filter has good size adaptability and can be cut and installed in a variety of structures. It is widely used in office buildings, subway ventilation systems, household air conditioners and other environments.

Application suggestions: Building an efficient multi-layer air purification system

In modern buildings, the release cycle of formaldehyde and TVOC pollution is long, the concentration fluctuates greatly, and the pollution sources are complex. It is often difficult to meet actual needs by relying solely on a single purification method. More and more fresh air system manufacturers are beginning to explore multi-level, multi-mechanism collaborative purification systems.

Lushen Environmental Protection has a rich product line in the field of catalytic air purification materials, covering a variety of forms from basic materials to structured filters, suitable for a variety of B-end application environments such as fresh air systems, air purifiers, central air conditioners, and vehicle purification modules. The following are some representative products and their typical application scenarios:

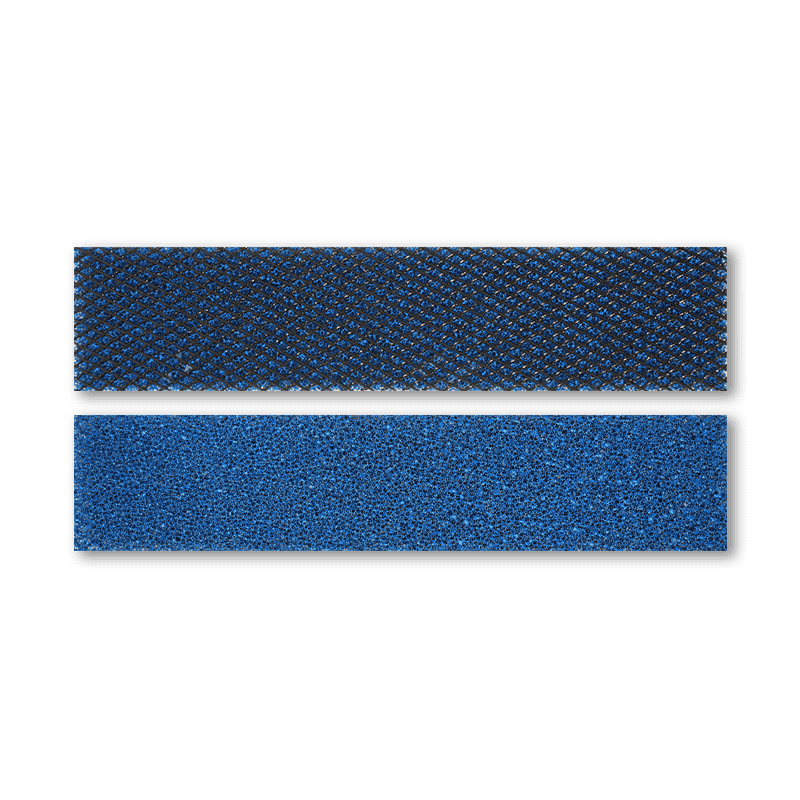

Sponge Cold Catalyst Filter Mesh

Using highly breathable open-pore PU foam as the carrier, it is suitable for fresh air main unit, air purifier, commercial purification module and other equipment, especially for application scenarios that require long-term and stable decomposition of organic pollutants such as formaldehyde and TVOC. Its room temperature reaction characteristics do not require external light sources, and are particularly suitable for system environments with insufficient light or limited energy consumption.

Paper-based Photocatalyst Filter Mesh

Using lightweight and high specific surface area paper as the carrier, nano-scale titanium dioxide is loaded. It is suitable for fresh air equipment equipped with UV light source or good natural light, wall-mounted purifiers and modular purification devices. It is suitable for quickly decomposing harmful gases such as formaldehyde and benzene, and improving the response speed of air quality.

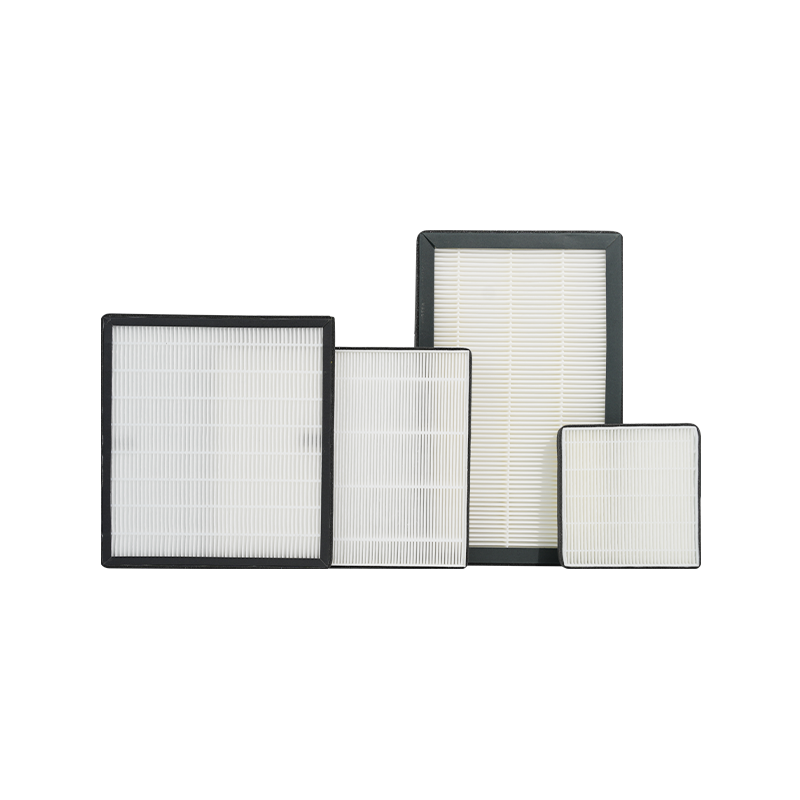

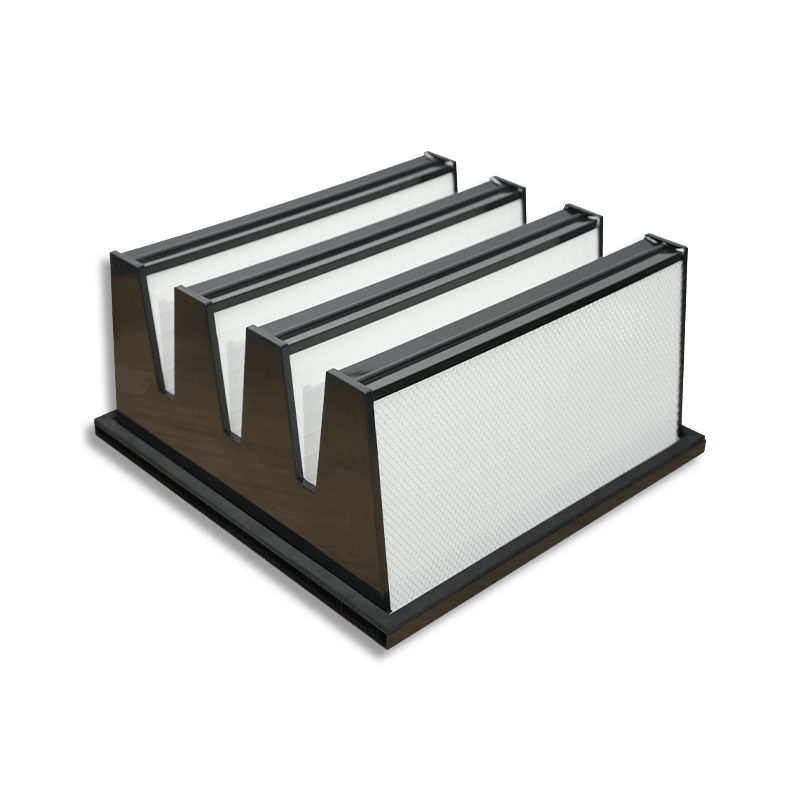

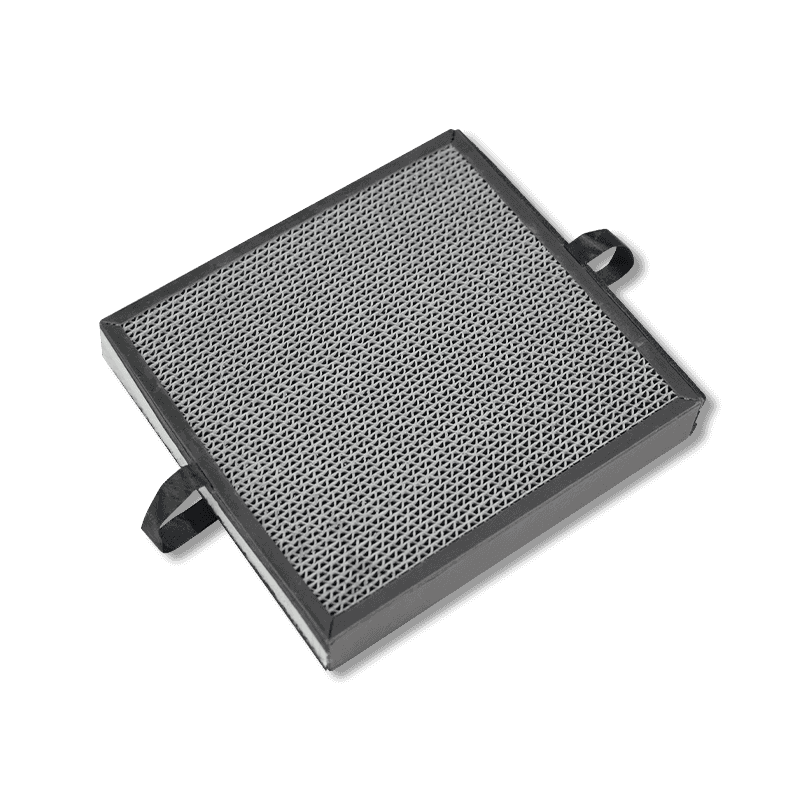

Catalyst HEPA Composite Filter

Suitable for places with high cleanliness requirements, such as medical fresh air systems, hotel air conditioning return air vents, etc. It integrates catalysts and HEPA filter elements into one, and meets the needs of particle and gas purification at the same time. It is suitable for terminal product design with high requirements for efficiency and structural integration.

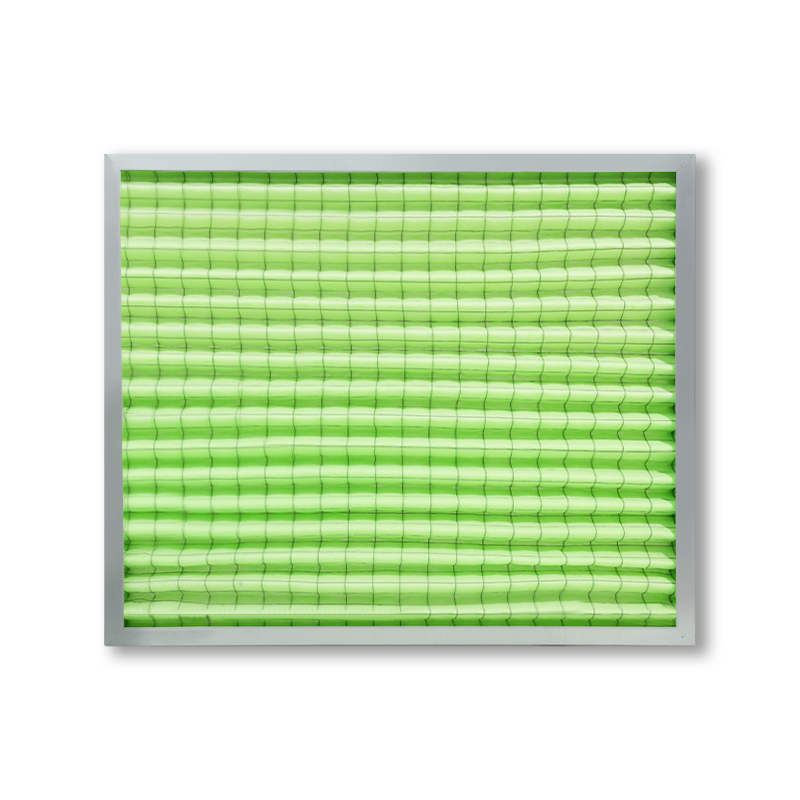

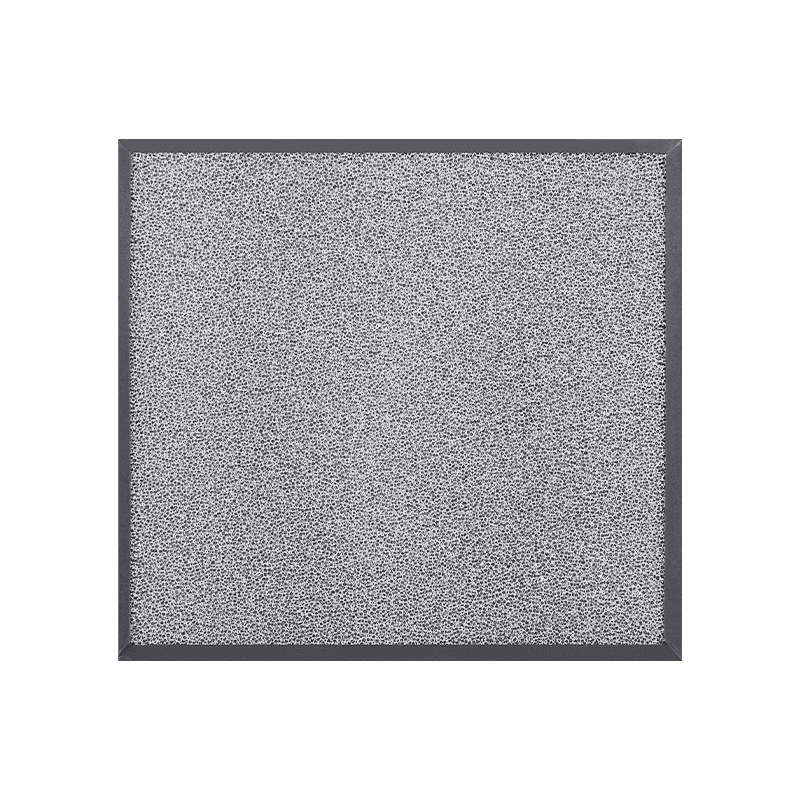

Catalyst Filter Materials

Contains various forms such as composite non-woven fabric substrates and foam substrates, which are easy to cut and composite. It is suitable for OEM customers to integrate according to system size and structure. It is widely used in customized equipment such as purifier modules, vehicle-mounted systems, and small fresh air modules.

Promote the value upgrade of air purification systems through material innovation

As consumers continue to pay more attention to indoor air quality, the treatment of gaseous pollutants such as formaldehyde and TVOC has become an important function that cannot be ignored in fresh air systems and air purification equipment. Compared with the traditional single technical path with particle filtration as the core, the "decomposition purification mechanism" constructed by catalytic functional materials is increasingly becoming an important direction for product upgrades.

Lyusen Environmental Protection has laid out a full-scenario air filtration material solution including cold catalyst sponge filters, paper-based photocatalyst filters, aluminum-based cold catalyst HEPA combination filters, catalyst filter materials, and spray-coated plate products based on different system structures, operating environments, and terminal needs, which are suitable for a variety of fresh air systems, purification modules, and integrated equipment. We always adhere to the core principles of stable material performance, flexible structural design, and high system adaptability to help customers achieve safer, energy-saving, and sustainable air purification goals.

English

English Español

Español 日本語

日本語