In recent years, the treatment of volatile organic compounds (VOCs) has become an increasingly serious environmental and health issue. VOCs are widely present in industrial production, paints, solvents, and household products, making them a major source of air pollution and a significant threat to human health. The emission of VOCs not only affects air quality but also leads to respiratory diseases, cancer, and other health problems. Due to its high adsorption performance, cost-effectiveness, and ease of application, activated carbon filtration technology is widely used for VOCs treatment.

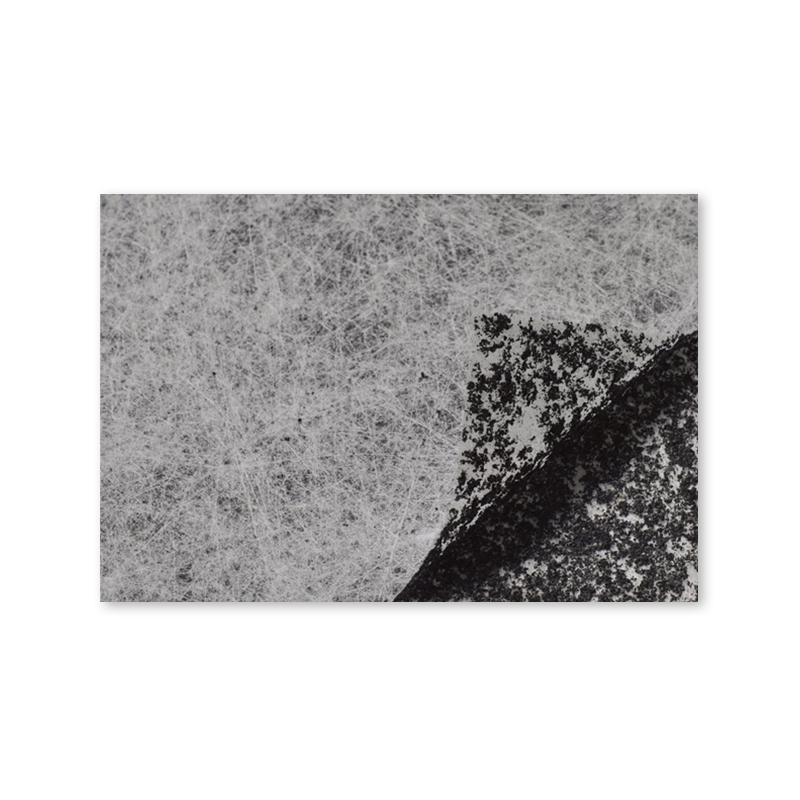

Activated carbon is a porous material with a very high specific surface area, which allows it to efficiently adsorb VOC molecules. With the continuous advancement of science and technology, significant progress has been made in the development and application of activated carbon materials.

1. Activated Carbon: A Leading Technology for VOCs Treatment

Activated carbon is a widely used porous material in water treatment, air purification, and other fields due to its high specific surface area (usually greater than 1000 m²/g) and powerful adsorption capabilities. Its working principle involves adsorbing VOC molecules to remove pollutants from air or water. Activated carbon has been widely used in VOCs treatment due to its excellent adsorption performance and high efficiency.

1.1 Characteristics and Mechanism of Activated Carbon

The adsorption of activated carbon is based on its highly developed porous structure, which provides a large number of adsorption sites for VOC molecules. Activated carbon’s pores are mainly classified as micropores, mesopores, and macropores, with different pore structures affecting the adsorption of various molecules. Micropores mainly adsorb small molecules, mesopores are suitable for medium-sized molecules, and macropores are better suited for larger VOC molecules.

The adsorption mechanism of activated carbon is mainly divided into physical adsorption and chemical adsorption. Physical adsorption primarily relies on Van der Waals forces and electrostatic interactions, while chemical adsorption involves the formation of chemical bonds between the VOC molecules and the carbon surface. For most VOCs, physical adsorption is usually the dominant mechanism, whereas for certain VOCs with stronger chemical properties (such as alcohols and aldehydes), chemical adsorption may play a more important role.

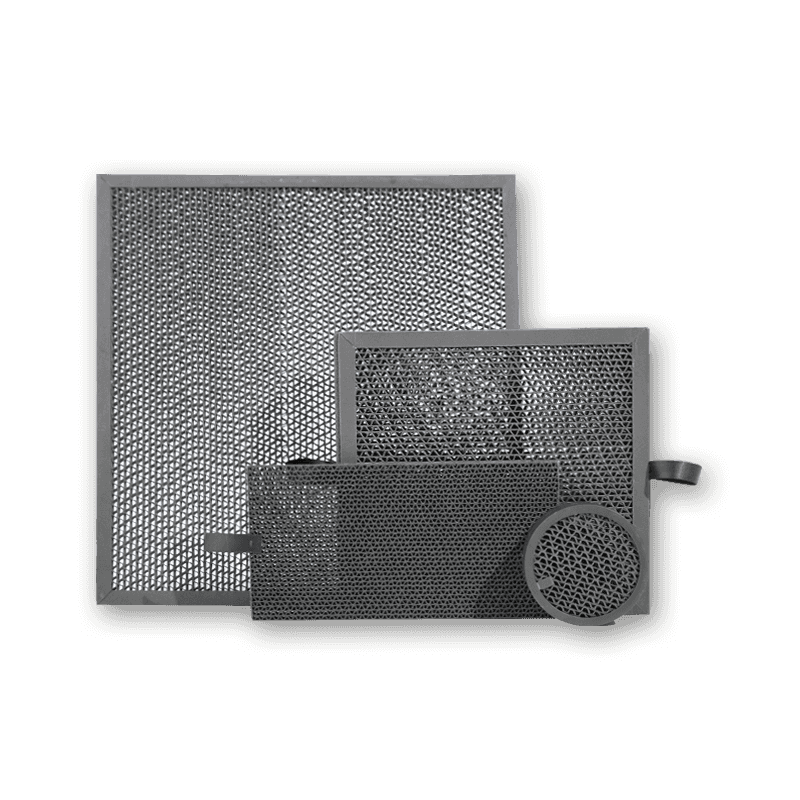

1.2 Types of Activated Carbon

Activated carbon comes in various raw material types, such as wood, coconut shell, coal, and synthetic activated carbon. Different raw materials have different physical and chemical properties, making them suitable for treating different types of VOCs.

Coconut Shell Activated Carbon: Coconut shell activated carbon typically has a higher specific surface area and is more effective at adsorbing smaller VOC molecules, making it ideal for air purification.

Coal-Based Activated Carbon: Coal-based activated carbon is commonly used for larger molecules and those with higher molecular weights, and it is generally more cost-effective.

Wood-Based Activated Carbon: Wood-based activated carbon is relatively inexpensive, with moderate adsorption performance, and is often used for general applications.

As the science of activated carbon materials continues to develop, researchers have also explored functionalized activated carbon, such as those doped with metal oxides or other reactive agents, to enhance their reactivity and adsorption capacity for specific VOCs.

2. Efficiency Evaluation of Activated Carbon Filter Materials in VOCs Treatment

The efficiency of activated carbon filter materials in VOCs treatment is primarily evaluated based on several key factors, including adsorption capacity, filtration efficiency, and regeneration potential.

2.1 Factors Affecting Adsorption Capacity

Adsorption capacity is the most critical indicator of the effectiveness of activated carbon filter materials in VOCs treatment. Several factors influence this capacity:

Specific Surface Area: The larger the specific surface area, the more adsorption sites activated carbon can provide, and the higher its adsorption capacity. Coconut shell activated carbon is known for its large specific surface area, making it more effective at adsorbing VOCs.

Pore Distribution: The pore distribution of activated carbon directly affects its ability to adsorb different types of VOCs. Micropores are suitable for small molecules, mesopores for medium-sized molecules, and macropores for larger VOCs.

Type of VOCs: Different VOCs molecules have varying polarities and volatilities. Polar VOCs (such as aldehydes and ketones) tend to form stronger interactions with activated carbon surfaces, making them more readily adsorbed, while non-polar VOCs (such as aromatic hydrocarbons) are more difficult to adsorb.

Temperature and Humidity: Temperature and humidity are crucial factors influencing the adsorption performance of activated carbon. High temperatures may cause VOCs to evaporate more quickly, reducing adsorption efficiency, while high humidity may occupy some of the adsorption sites on activated carbon, lowering its effectiveness.

2.2 Evaluation of Filtration Efficiency

Filtration efficiency refers to the ability of an activated carbon filter system to remove VOCs from air or water streams. The filtration efficiency of activated carbon is influenced by the following factors:

VOC Concentration: The higher the VOC concentration, the quicker activated carbon reaches saturation, resulting in decreased filtration efficiency. Therefore, maintaining reasonable VOC concentrations is critical for improving filtration efficiency.

Flow Rate and Air Distribution: The flow speed and uniformity of airflow in the filtration system also affect its efficiency. If the flow rate is too high, VOC molecules may not have sufficient time to come into contact with activated carbon, lowering the overall effectiveness.

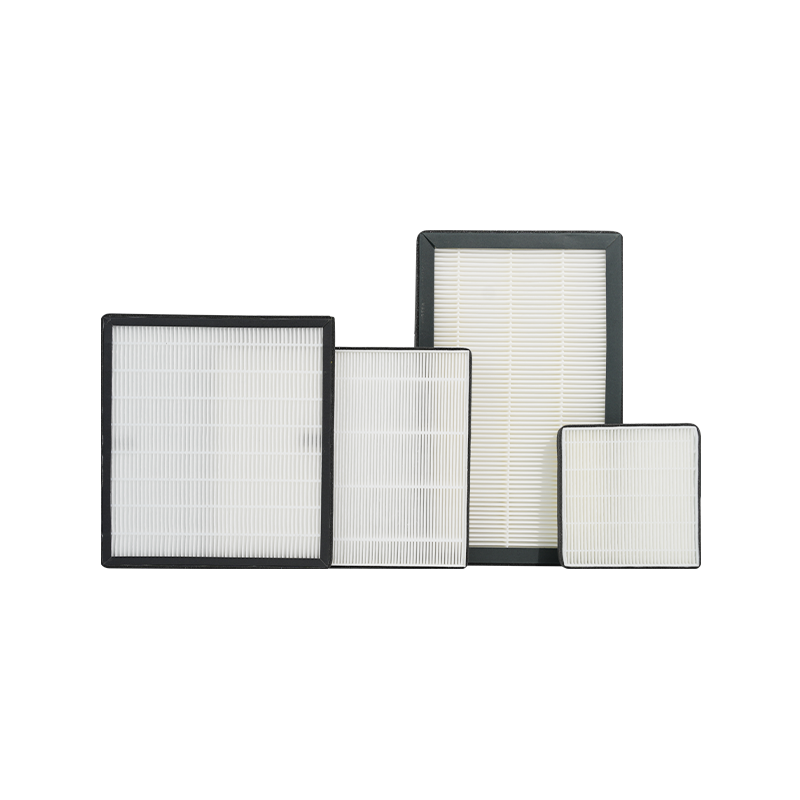

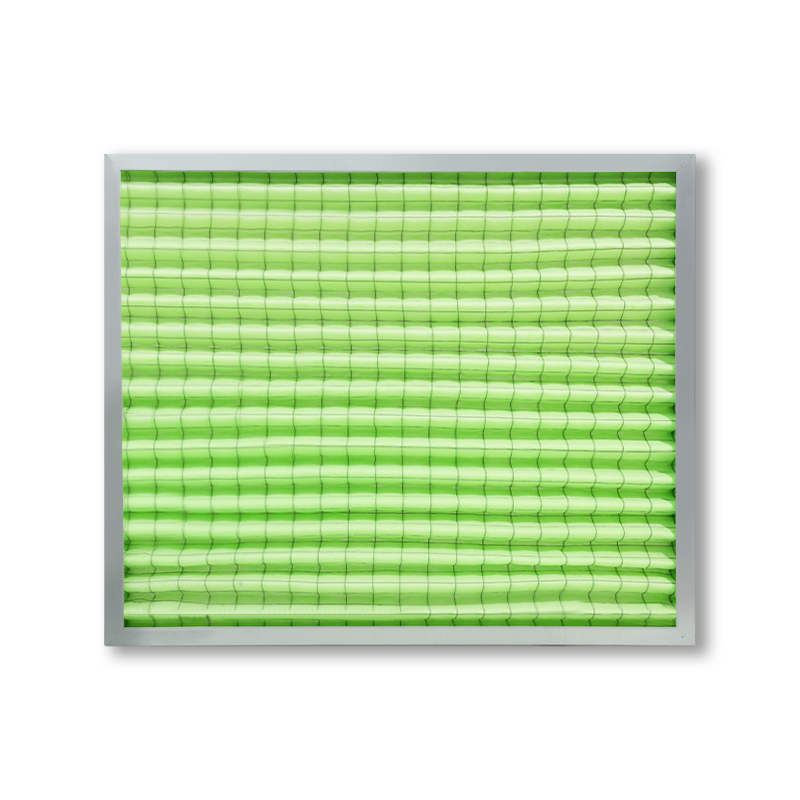

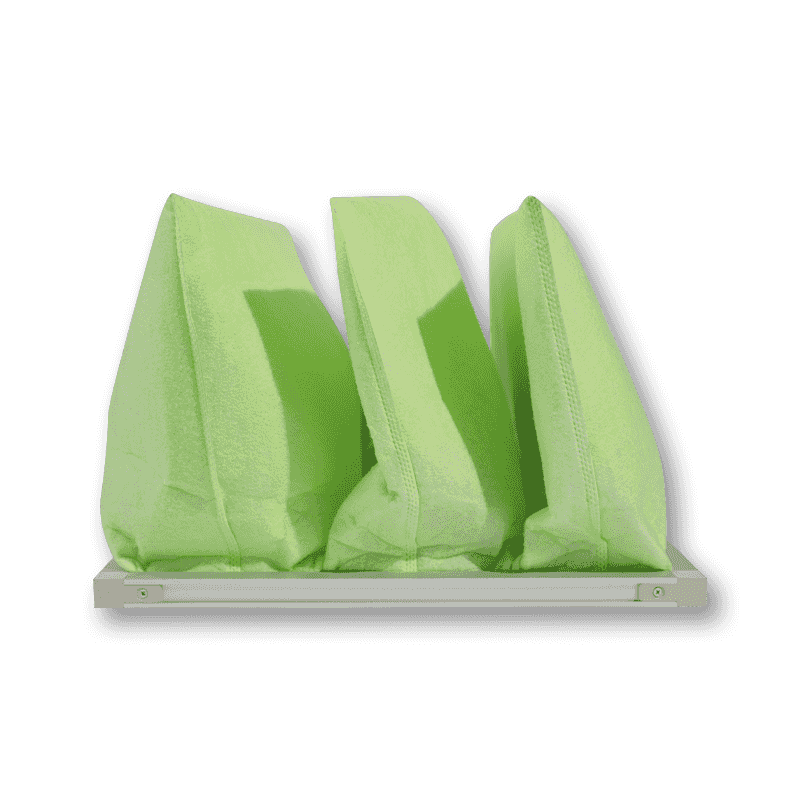

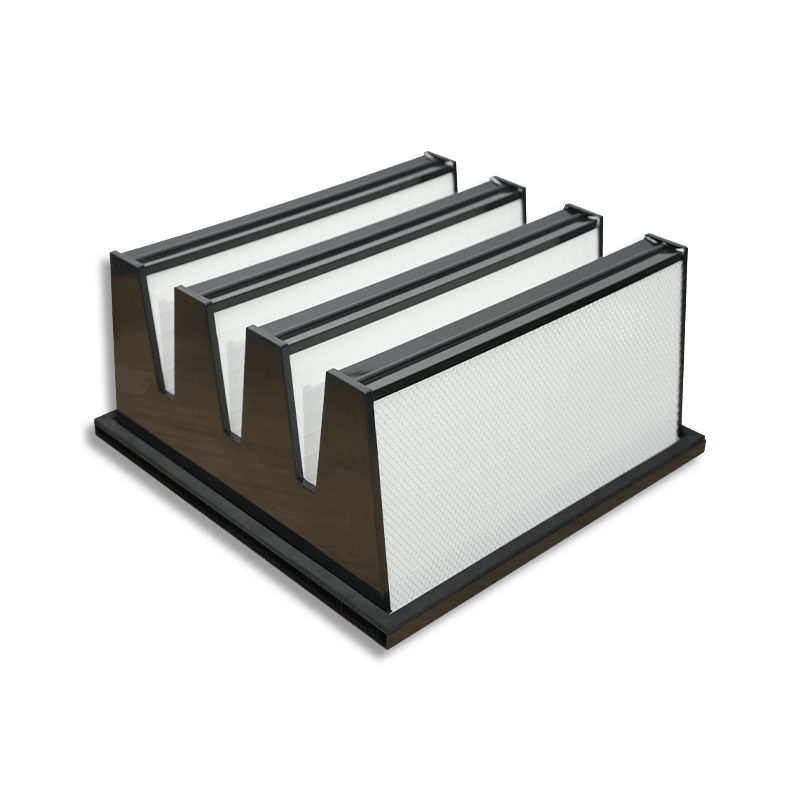

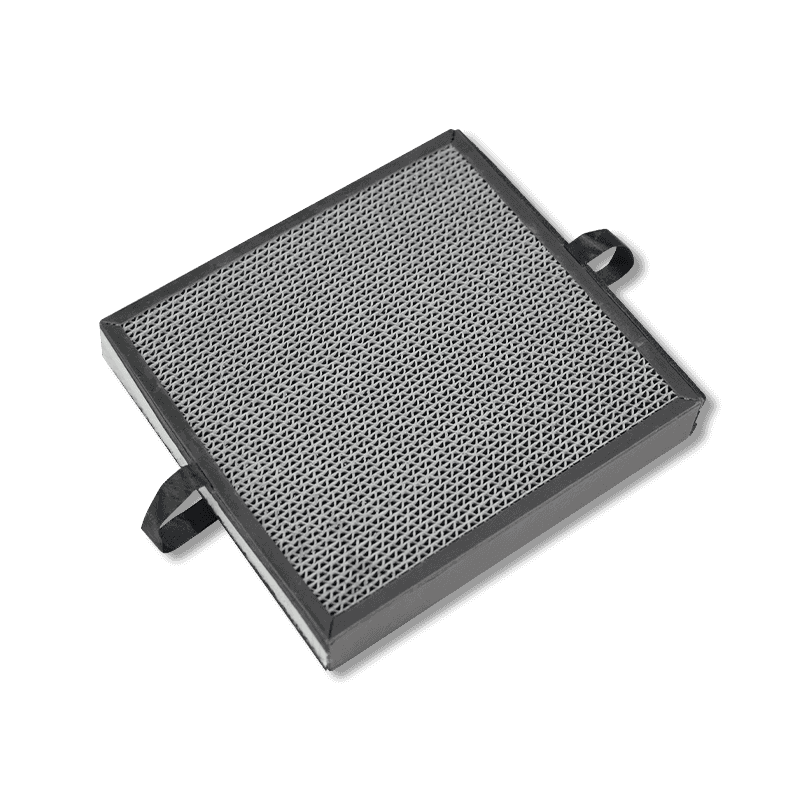

Filter Design: The design of the activated carbon filter also plays a crucial role in filtration efficiency. High-efficiency filter designs often include multi-stage filtration systems, where activated carbon is used in conjunction with other materials, such as zeolites or silica gels, to enhance the overall performance.

2.3 Evaluation of Regeneration Potential

As activated carbon adsorbs increasing amounts of VOCs, its adsorption capacity gradually declines. Therefore, regeneration is a crucial aspect of evaluating the performance of activated carbon filter materials. Common regeneration methods include:

Thermal Regeneration: This method involves heating saturated activated carbon to a certain temperature, allowing adsorbed VOCs to desorb and restoring its adsorption capacity. This process typically requires high temperatures and significant energy consumption.

Steam Regeneration: Steam is used to treat activated carbon, utilizing its thermal energy and solubility properties to help remove adsorbed VOCs.

Microwave Regeneration: Recently, microwave-based heating technologies have gained attention for regenerating activated carbon. This method is more energy-efficient and has a lower environmental impact compared to traditional thermal regeneration.

3. Considerations in Using Activated Carbon for VOCs Treatment

Activated carbon is a highly effective solution for VOCs removal, but its application involves certain factors that influence its long-term performance and efficiency. These factors include:

3.1 Adsorption Capacity and the Need for Maintenance

As activated carbon adsorbs VOCs, its adsorption capacity naturally decreases over time. Eventually, it reaches a point where it can no longer effectively capture additional VOC molecules. At this stage, the material requires either regeneration or replacement. Regeneration can restore some of its capacity, though not always to its original state. As a result, routine maintenance or replacement of the activated carbon may be necessary to maintain optimal performance, which can lead to higher operational costs.

3.2 Influence of Humidity and Temperature Conditions

The performance of activated carbon is influenced by environmental factors such as humidity and temperature. In environments with high humidity, water molecules can occupy some of the adsorption sites, which limits the amount of VOCs that can be captured. Both very high and very low temperatures can impact the adsorption process, reducing the carbon’s efficiency. These factors should be carefully considered when using activated carbon in varying environmental conditions to ensure consistent filtration performance.

3.3 Durability and Lifespan of Activated Carbon Filters

Although activated carbon filters can be regenerated to restore their adsorption capacity, they do have a finite lifespan. Over extended use, the material may undergo structural changes or physical degradation, reducing its ability to adsorb VOCs effectively. To optimize the use of activated carbon, it is important to consider its durability and the need for periodic regeneration or replacement. Research into developing more durable and long-lasting materials continues to be an important area of focus for improving the efficiency of activated carbon filters.

4. Future Directions

Although activated carbon filter materials have made significant strides in VOCs treatment, there are still numerous technical and economic challenges to overcome. The future development of activated carbon materials will focus on improving their efficiency, reducing costs, and extending their lifespan. Key areas for future development include:

4.1 Development of High-Performance Functionalized Activated Carbon

In recent years, significant progress has been made in the development of functionalized activated carbon, with many researchers focusing on combining activated carbon with other materials to give it more specific properties. For example, doping metal oxides (such as titanium, zinc, or aluminum) into activated carbon can significantly improve its adsorption and catalytic decomposition abilities for specific VOCs. These composite materials not only adsorb VOCs but also catalytically break down harmful substances, offering enhanced purification capabilities.

Coating and surface modification techniques are being developed to alter the functional groups on the surface of activated carbon, which can increase its selective adsorption of certain harmful substances. These functionalized modifications may make activated carbon more effective in treating VOCs with specific chemical properties, such as halogenated organic compounds.

4.2 Application of Nanotechnology in Activated Carbon

Nanotechnology has also shown great potential in the development of activated carbon materials in recent years. Nano-structured activated carbon, due to its larger specific surface area and stronger adsorption capacity, could become an ideal material for future VOCs treatment. By introducing nanomaterials (such as nano-metal oxides or nano-carbon materials) into the pores of activated carbon, researchers can significantly improve its adsorption rate and capacity.

The inclusion of nanomaterials not only enhances the adsorption capacity but also improves the regeneration potential of activated carbon. For instance, nanomaterials have higher thermal stability and stronger chemical reactivity, which can help improve energy consumption and regeneration efficiency, making activated carbon more sustainable and durable.

4.3 Development of Smart and Multifunctional Filtration Systems

With the development of information technology and the Internet of Things (IoT), smart filtration systems are gradually becoming a trend. Smart activated carbon filtration systems can automatically adjust the operation based on parameters such as VOC concentrations, temperature, and humidity. For example, the system can automatically activate additional filter layers or adjust airflow speed when high VOC concentrations are detected, improving treatment efficiency.

Multifunctional filtration systems are gaining attention. These systems combine activated carbon with other advanced filtration technologies (such as photocatalysis, ozone oxidation, biological filtration, etc.) to form a comprehensive treatment system capable of removing not only VOCs but also other air pollutants (such as odors and particulate matter). This synergistic effect from multiple technologies will greatly enhance the overall efficiency and applicability of the system.

4.4 Environmental Sustainability and Green Development

Environmental sustainability is a critical focus in the future development of activated carbon filtration materials. The production of activated carbon typically requires high-temperature heating, which consumes a significant amount of energy and has environmental impacts. To mitigate this, researchers are exploring greener production methods. For example, using biomass materials (such as agricultural waste and wood residues) to produce activated carbon can reduce production costs and conserve natural resources.

The development of low-energy, high-efficiency regeneration technologies can further enhance the sustainability of activated carbon. By improving the regeneration process to reduce energy consumption and environmental impact, activated carbon materials can be used more sustainably in VOCs treatment applications.

4.5 Economic Feasibility and Large-Scale Applications

While activated carbon filtration technology is highly efficient in VOCs treatment, its high initial investment and maintenance costs remain major barriers to large-scale application. Therefore, lowering the production costs of activated carbon, improving its recyclability, and reducing maintenance expenses will be crucial for future development. Optimizing production processes, improving raw material selection, and enhancing regeneration efficiency are all strategies that will contribute to reducing the overall cost.

As urbanization accelerates, the issue of urban air pollution becomes increasingly severe, leading to growing demand for VOCs treatment. Large-scale activated carbon filtration facilities will become essential components of urban air purification systems. Integrating activated carbon filtration technology into urban air governance frameworks will be crucial for expanding its application.

English

English Español

Español 日本語

日本語