In applications such as air purification, industrial deodorization, and fresh air systems, activated carbon filter materials have become the preferred material for removing odors and harmful gases due to their strong adsorption capacity. The adsorption of activated carbon is a limited and irreversible process. Once saturation is reached, it will lose its purification effect and may even cause secondary pollution. We need to learn to identify whether the activated carbon filter material is saturated and replace it in time, which is the key to ensuring air quality.

The main indicators for judging the adsorption saturation of activated carbon

Odor change: The reappearance of odor indicates that the carbon layer is saturated

The main function of activated carbon is to absorb odors, harmful gases and volatile organic compounds (VOCs) in the air. When the filter material is close to saturation, its adsorption efficiency drops significantly, causing the odor that was originally effectively removed to be perceived again in the space.

When you find that the odor of indoor formaldehyde, TVOC, etc. is significantly enhanced, or the purification effect of the equipment is not as good as before, even if the particulate matter is effectively filtered, you should focus on checking the activated carbon layer.

Especially in closed spaces (such as cars, hotel rooms, and conference rooms), the odor sensitivity is higher. It is recommended to establish an odor baseline perception at the beginning of use. Once a significant change occurs, you can preliminarily judge whether the carbon layer is saturated.

Color difference of filter material: Color change reflects the adsorption state

Some activated carbon filter materials (especially granular carbon or spray-on activated carbon) will change color during use due to the adsorption of particulate matter and organic pollutants. Common manifestations include: from black to dark gray or brown,

color spots or obvious regional color difference on the surface, the edge of the filter material is darker than the middle, etc., indicating that air pollutants accumulate locally, especially under high-load conditions, the activated carbon particles oxidize strongly and the color difference is more obvious. Although color difference is not a feature that all filter materials obviously reflect, if you can observe that the filter material is overall dark and loses its original luster, it is also an important basis for judging aging.

Increased wind resistance: Changes in system operating parameters prompt

Although the activated carbon filter layer does not block particles with micropores like the HEPA layer, it will still increase wind resistance during use due to particle accumulation and changes in air humidity. When the overall air volume of the system decreases or the fan noise increases, the wind resistance index should be tested to assess whether it is caused by blockage of the carbon layer.

Some industrial customers will use wind resistance monitoring modules when using Activated Carbon Filter Materials and set warning values. Once the wind resistance exceeds the threshold, the maintenance process will be started. This method is suitable for long-term operation and management of mass engineering projects or public facilities.

Operation duration: It is recommended to set a regular replacement cycle.

In the absence of electronic monitoring, setting a standard replacement cycle is a safe and controllable method. Taking activated carbon adsorption of formaldehyde as an example, generally under 24-hour continuous operation, its effective cycle is about 3-6 months, depending on the pollution intensity, humidity, temperature and other factors of the use environment.

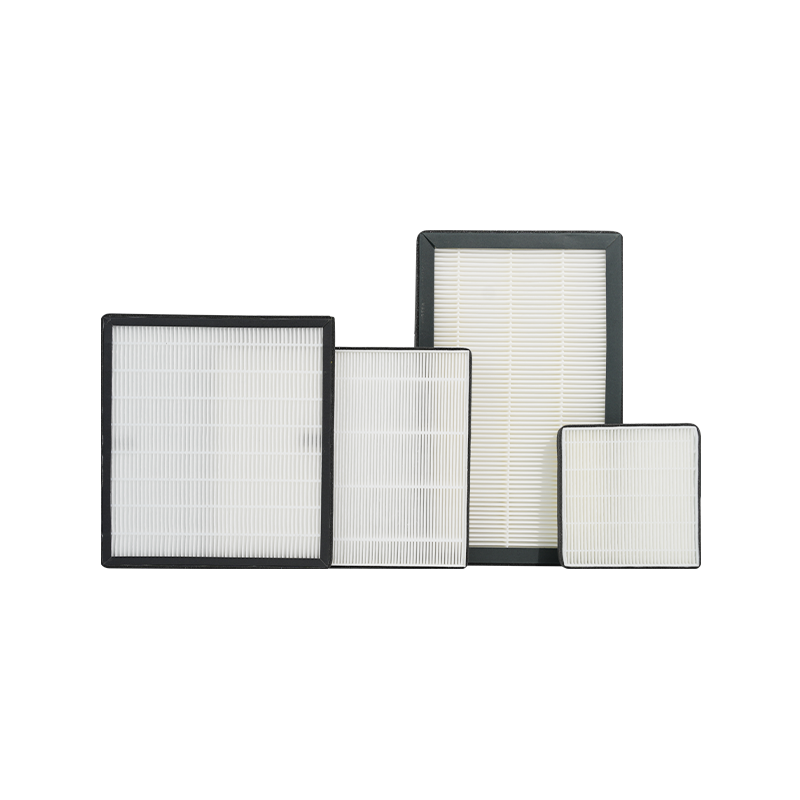

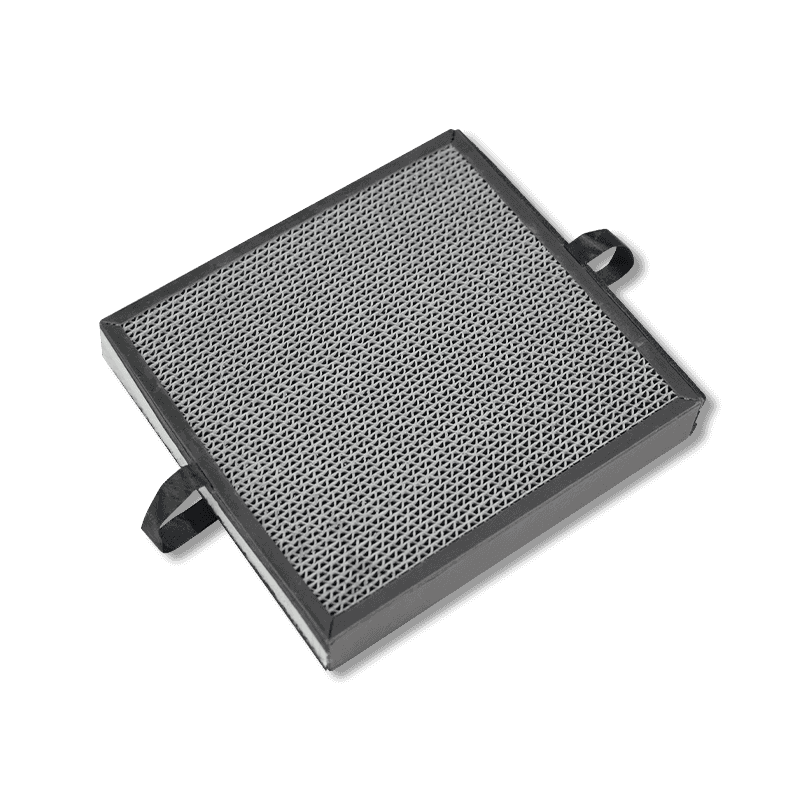

For customers using our Honeycomb Activated Carbon Combined HEPA Filter fresh air system, it is recommended to formulate a replacement plan based on the following dimensions:

Newly renovated places: Check and replace every 3 months

Office/residential environment: Replace every 6 months

Industrial/high-concentration VOC environment: Need to be shortened to once every 2-3 months

Reasonable storage and use to extend the effective period

When not in use, the activated carbon filter material should be stored away from light, sealed, and dry to avoid premature moisture absorption and saturation. When in use, it should also be avoided from direct sunlight and high humidity environments, otherwise it will accelerate failure.

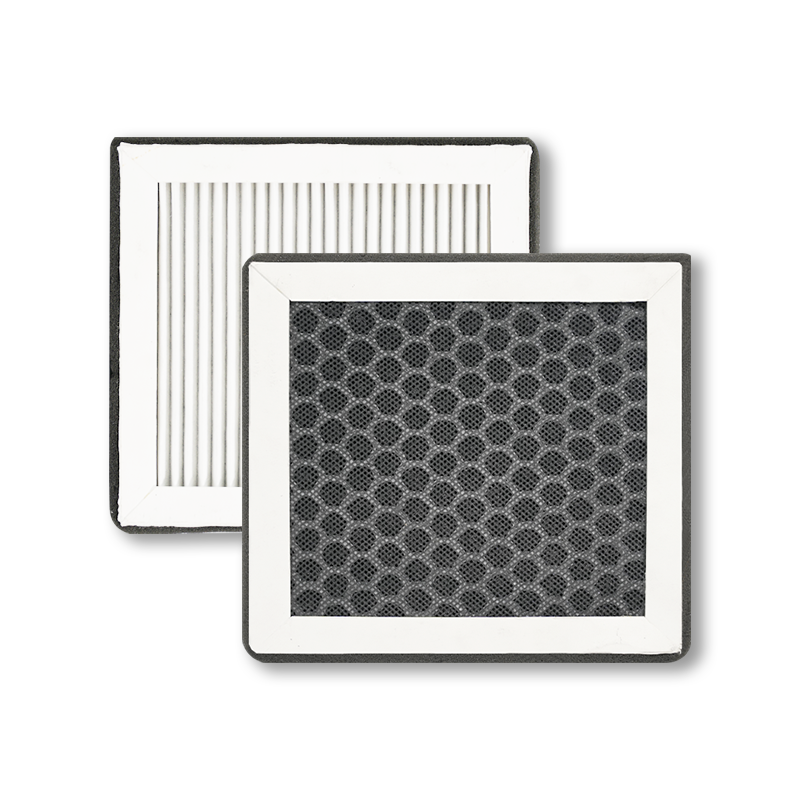

If you need to extend the service life of the filter material, our company can also provide moisture-proof coated Composite Activated Carbon Filter Media, which has higher stability and structural integrity, and is suitable for long-term operation in complex scenarios.

Develop a filter material maintenance and replacement plan

The lifespan of activated carbon filter materials varies greatly depending on the frequency of use and air pollution concentration in different scenarios. To ensure the filtering effect and extend the life of the equipment, customers are advised to develop a maintenance plan based on the following standards:

Daily home environment (bedroom, living room, etc.)

It is recommended to check the filter material every 3 to 6 months

Pay special attention to the changes in air quality during the change of seasons

If you find that the air has odor or the wind speed is reduced, replace it in time

Severely polluted scenes (kitchens, garages, industrial workshops, etc.)

The concentration of oil smoke, chemical gases, and particulate pollution in the air is high

It is recommended to check or replace it regularly every 1 to 3 months

It is recommended to use a particulate pre-filter to extend the life of the carbon layer

High-cleanliness places (hospitals, laboratories, dust-free workshops)

The air quality requirements are extremely high, and it is recommended to use monitoring equipment

It is safer to adopt a regular replacement system (such as once a month)

The air quality sensor linkage replacement reminder system can be introduced

Usage suggestions

Record the time and label each time the filter material is replaced

A maintenance ledger can be established to track the replacement cycle for a long time

Keep the equipment clean to prevent the filter material from failing due to moisture

Advantages of our activated carbon filter materials

Selecting high-quality activated carbon filter materials is the basis for ensuring purification efficiency and service life. Our company focuses on the research and development and production of high-performance air purification materials. Our products have the following unique advantages:

High iodine value activated carbon, strong adsorption

We select high iodine value natural or modified activated carbon, which has a developed microporous structure and strong adsorption capacity. It can effectively remove harmful gases such as formaldehyde, benzene, ammonia, hydrogen sulfide, and efficiently adsorb daily pollution sources such as smoke, odor, and pet odor, creating a clean and healthy breathing environment.

Multiple specifications of substrates, flexible adaptation

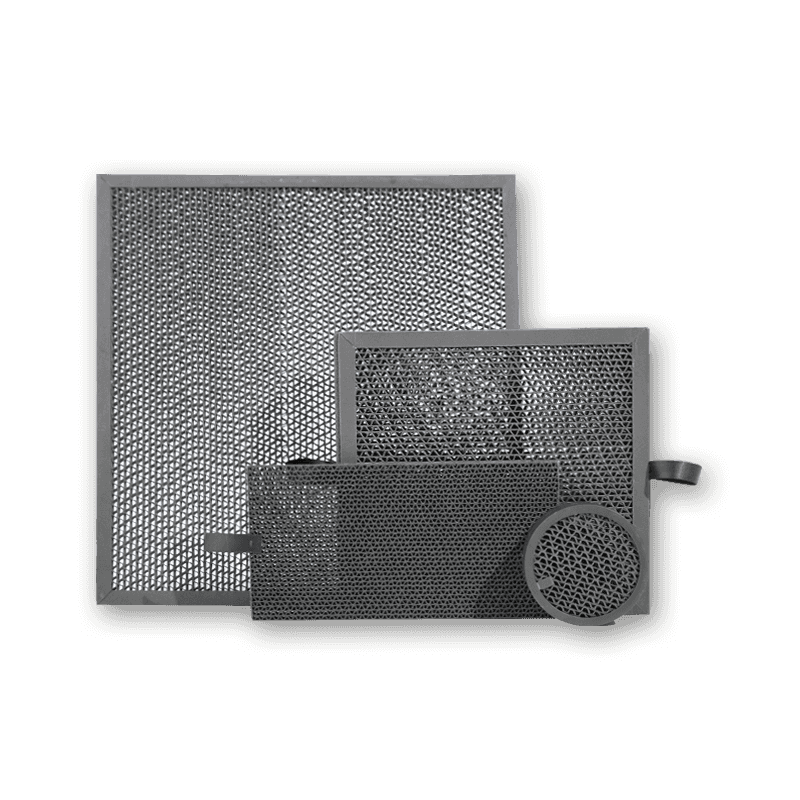

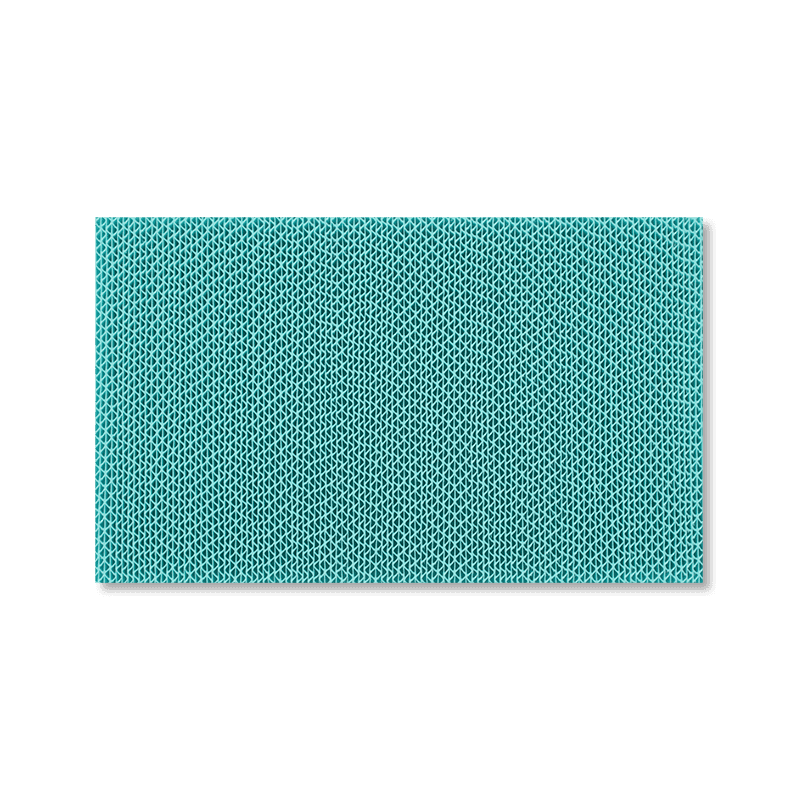

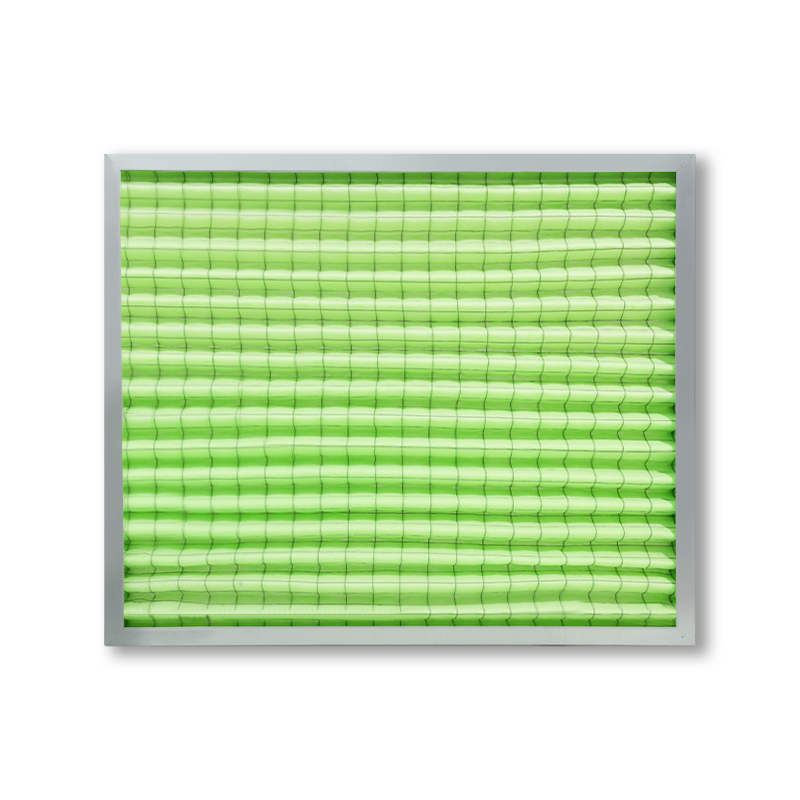

According to different equipment structures and usage environment requirements, we provide the following types of activated carbon filter products:

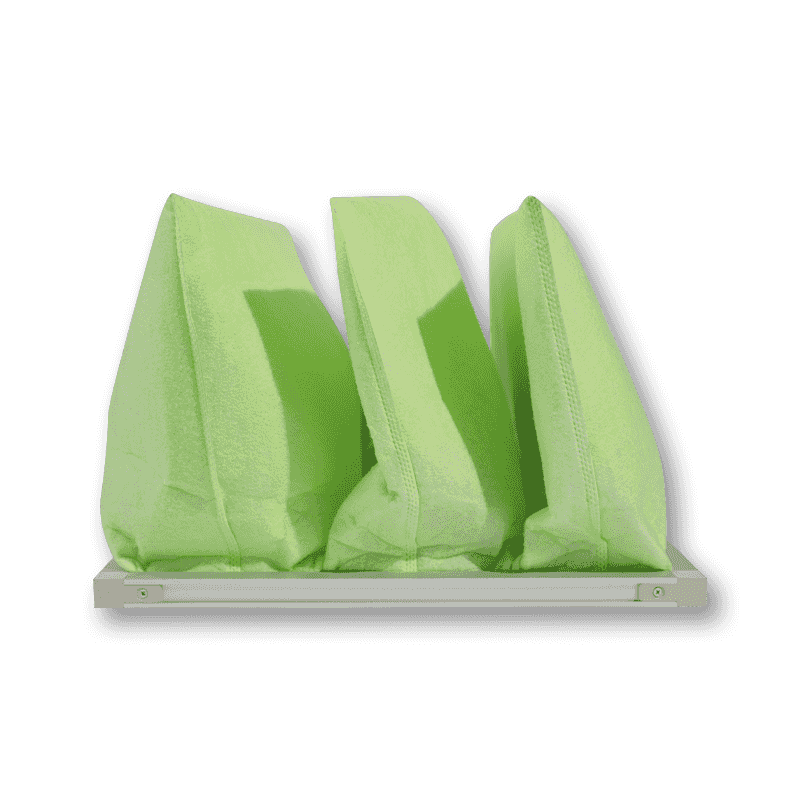

Sponge type filter material: good elasticity, easy to cut, suitable for air purifiers and air conditioning systems;

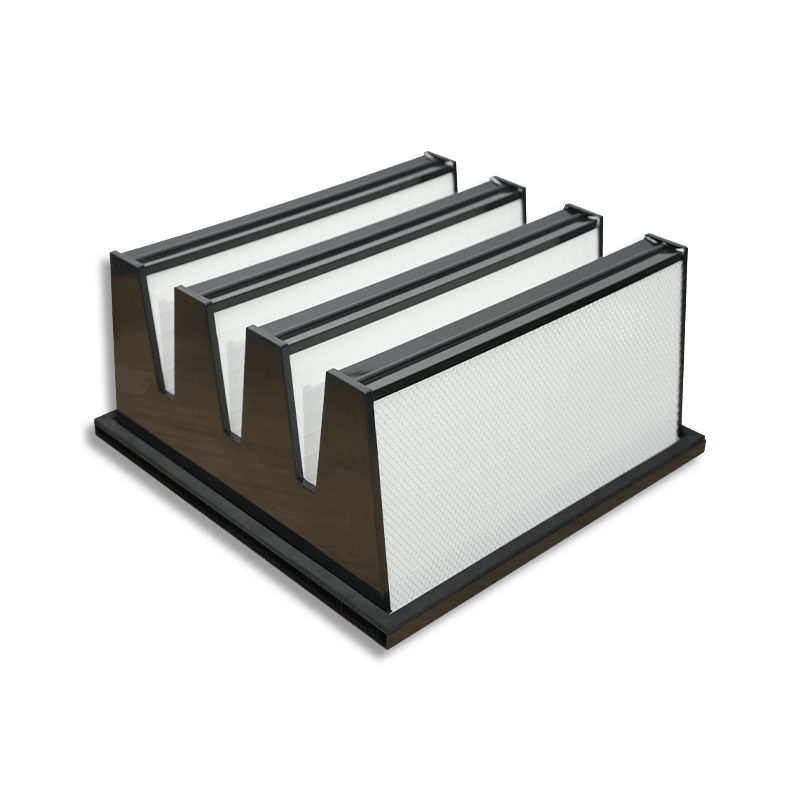

Fiber composite filter material: high filtration accuracy, good structural strength, widely used in central air conditioning and fresh air systems;

Paper activated carbon: light, cost-effective, suitable for one-time use scenarios;

Cloth/non-woven filter material: strong flexibility, adaptable to complex structures, commonly used in automotive air conditioning and industrial odor control equipment.

Although the activated carbon filter looks ordinary, its purification performance directly affects the overall air quality. Through multi-dimensional indicators such as "odor identification, color comparison, wind resistance monitoring, and operation cycle", customers can more scientifically judge the adsorption saturation state and reasonably arrange maintenance and replacement plans.

As a professional manufacturer of activated carbon filter materials, Lyusen Environmental Protection provides air purification material solutions in various specifications and forms, including granular, honeycomb, and composite types, supports customized development and batch supply, and helps B-end customers achieve more efficient and lasting purification effects in various scenarios.

English

English Español

Español 日本語

日本語